A Proton, An Electron—And Thou

Hindenburg meets Hiroshima, what could possibly go wrong?

[Credit: iStock]

I’ve argued ad nauseam that battery-electric propulsion is poorly suited for most full-scale aircraft applications. To deliver a certain amount of power for a certain length of time requires a weight in batteries 15 times that of conventional fuels. Batteries may serve for flights at low speeds over short distances, such as an hour of student instruction, but they don’t lend themselves to passenger- or cargo-carrying trips of many hundreds of miles at hundreds of miles an hour. For that, you need fuel.

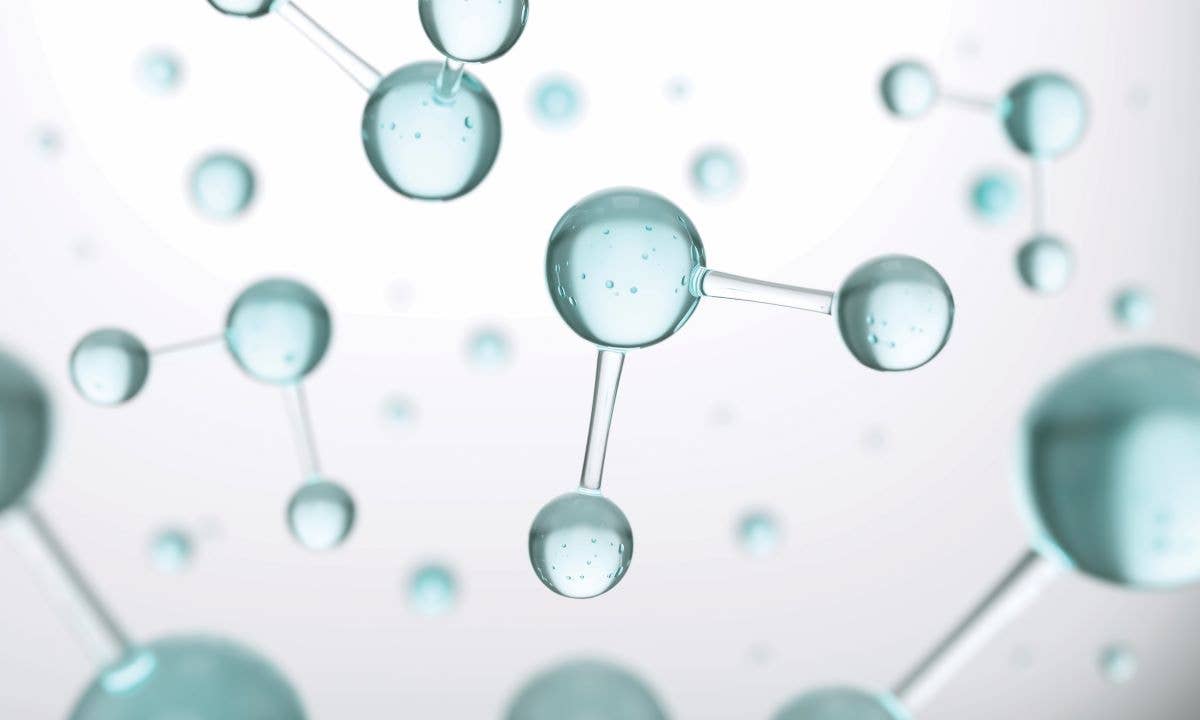

Among potential aviation fuels that are not hydrocarbons like gasoline and ethanol, hydrogen is currently the most promising. Seated at the head of the periodic table, hydrogen is the lightest element, a minimalist atom consisting only of a proton and an electron. It is not scarce: three-quarters of the mass of the universe is hydrogen. Hydrogen contains lots of energy—about three times as much, per pound, as gasoline. In that respect, it’s at the opposite end of the spectrum from batteries and far ahead of any hydrocarbon fuel.

If you're not already a subscriber, what are you waiting for? Subscribe today to get the issue as soon as it is released in either Print or Digital formats.

Subscribe NowUnfortunately, its density at sea level pressure is 1/8000 that of gasoline, and, since energy is proportional to mass, not volume, it must be stored in condensed form to be a practical fuel. It can be cooled to an extremely low temperature and stored as a liquid, but the liquid form has significant disadvantages, notably that it must be taken aboard shortly before flight and the tanks have to be extraordinarily well insulated. The approach used by car manufacturers, and likely to be adopted by builders of hydrogen powerplants for airplanes, is to store gaseous hydrogen under high pressure in carbon-fiber tanks. With the high energy content of the compressed hydrogen somewhat compensating for its low density, cars like Toyota’s Mirai and Hyundai’s NEXO are able to get reasonable range (around 300 miles) out of 700-bar (10,000-psi) tanks that fit unobtrusively within the chassis of the vehicle.

Hydrogen can fuel reciprocating and turbine engines, but that avenue, while it has familiarity to recommend it, is not the one currently getting the most attention. Instead, hydrogen would be used to produce electricity to drive electric motors.

The apparatus that makes electricity out of hydrogen is called a fuel cell. Instead of storing an electrical potential as a battery does, a fuel cell generates one as it goes along. Various kinds of fuels and cycles are possible. A hydrogen fuel cell works, in broad outline, by separating the hydrogen molecules’ positively-charged protons from their negatively-changed electrons with a chemical catalyst. A filtering membrane, permeable to protons but not to electrons, divides the particles into two groups with opposite electrical charges. The particles are finally reunited through an external electrical circuit—this is where the useful work is done—and combined with ambient oxygen to produce water.

One of the fuel cell’s great advantages over the internal combustion engine is that it has no moving parts and therefore very high reliability—always a desirable thing in aviation. Another, on general environmental grounds, is that its exhaust consists principally of water. Advocates of hydrogen power tend, however, to gloss over the fact that hydrogen is not found lying around on earth, like coal or oil, waiting to be scraped up or pumped out. It exists mainly in chemical compounds, notably water, from which it must be forcibly liberated before it can be used. The creation of hydrogen gas requires energy, and most of that energy comes, today at least, from fossil-fueled powerplants.

The electrical potential across a single fuel cell is small—currently less than one volt—and so for practi-cal applications multiple cells, combined in a “stack,”are connected in series and parallel to produce a desired voltage and power output. A powertrain consisting of such a stack, an electric motor, and the required power controller is comparable in size and weight to a conventional reciprocating or turbine engine. It will almost certainly be cheaper to manufacture and have a much longer service life. It is more efficient, so it rejects less waste heat and entails less cooling-related drag. Electric motors are compact and permit slender, perfectly streamlined nacelles and cowlings. They are also highly reliable. Furthermore, because of the high energy content of hydrogen and the superior efficiency of the fuel cell, less fuel—a fifth as much by weight—is required for a given mission.

So far, so good. Now we come to the hard part, which is entirely related to the inconveniently low density of hydrogen. The happy coincidence that wings appropriately sized for flight have hitherto provided the internal volume for an appropriate supply of fossil fuel disappears when the fuel is hydrogen. Even assuming storage at 700 bar, the hydrogen required to go a given distance at a given speed takes up about five times as much space as conventional fuels would. And you can’t put compressed hydrogen into just any unused compartment; you have to store it in strong spherical or cylindrical containers with fancy impermeable liners,and these have to be placed somewhere near the center of gravity, or evenly distributed around it. The weight saved in fuel mass, luckily, may cancel some or all of the added burden of special tanks.

Several firms, including Boeing and Airbus, have developed fuel-cell prototypes in the past. A California company, ZeroAvia, has replaced one engine on each of two twin-engine Dornier 228s with 600 kW (800 hp) hydrogen-electric powertrains; one is currently being tested in England and the other in California. ZeroAvia has also announced a program with Textron to convert a Cessna Caravan to fuel cell power. Other conversion projects have been announced by other firms, but as far as I know they are not so far advanced as ZeroAvia’s are.

Dan Raymer, author of the now ubiquitous aeronautical engineering textbook, Aircraft Design: A Conceptual Approach, had a long career at Lockheed with the happy assignment of dreaming up novel configurations for futurist airplanes. He took a look at hydrogen fuel in the 1970s and conceived a three-body airplane consisting of a central fuselage and two huge liquid-hydrogen-filled booms skewered like kebabs on a canard and wing. The arrangement anticipated those of two globe-circling Rutan designs,Voyager and Global Flyer, which were, similarly, airplanes requiring outsize volumes of fuel. Other schemes involve conventional layouts with very fat fuselages. All approaches increase drag; we may have to accept some performance compromises for the sake of a limitless supply of clean fuel.

I cannot resist closing with a comment from Raymer, who wrote, in response to my request for his insights on hydrogen power, “If we don’t go straight for nuclear-powered aircraft then probably the best 2050 option for flight would be hydrogen fuel, with the hydrogen made by little nuclear power plants located on or near each airport. Hindenburg meets Hiroshima—what could go wrong?”

He’s kidding—I think.

This article was originally published in the February 2023 Issue 934 of FLYING.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox