Baby Steps Toward Space Mining and Manufacturing

Emerging technology behind new satellite servicing spacecraft could someday lead to asteroid mining and space manufacturing.

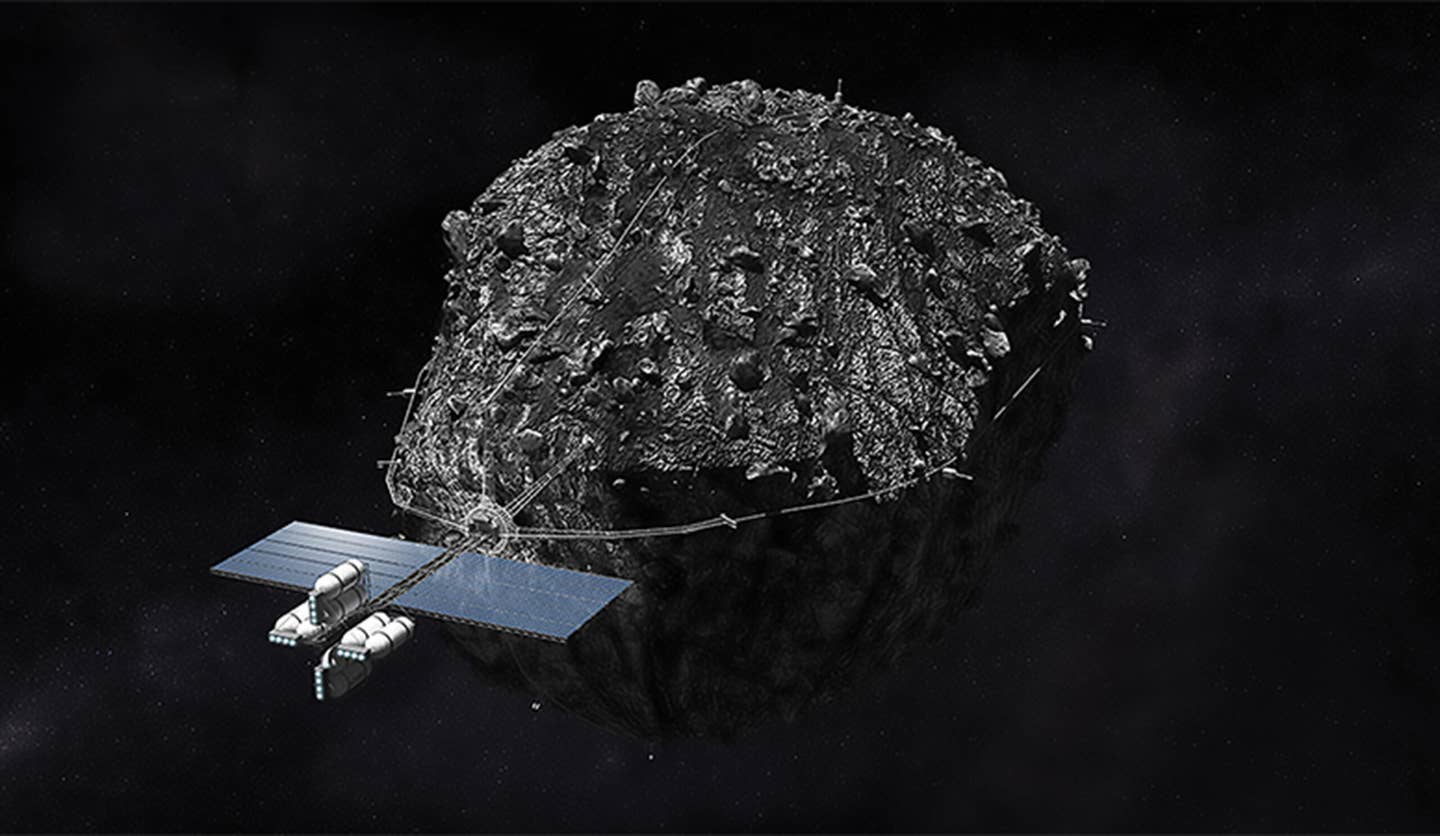

A company called Deep Space Industries developed this asteroid harvester concept. [Courtesy: NASA]

Much of the attention surrounding space exploration focuses on human space travel. But one of the most exciting and promising areas of space research and development surrounds the use of robotics and autonomous spacecraft.

Imagine fleets of automated, spacefaring robots with sophisticated technology designed to capture orbiting space junk and harvest it for raw materials.

Or, imagine an uncrewed orbiting spacecraft that has the ability to actually build satellites and other useful machines while floating in space.

Or, what if engineers built small, autonomous machines that could repair and maintain a space station orbiting the moon?

Far fetched? Perhaps. Nonetheless, ideas like these are currently being discussed by scientists and other experts focused on transforming the space around Earth into an active environment with valuable benefits to society.

Some of the technological first steps required to achieve these ambitious concepts are happening in laboratories like The Rendezvous Proximity Operations and Docking (RPOD) Lab, operated by Northrop Grumman (NYSE: NOC) subsidiary SpaceLogistics, outside Washington, D.C.

Engineers at the RPOD Lab helped develop SpaceLogistics’ Mission Extension Vehicle (MEV), the first operational automated commercial spacecraft to successfully approach a satellite in geosynchronous orbit (GEO) 22,000 miles from Earth, dock with it, and provide propulsion and pointing control. The MEV-1 mission in 2020 was a huge leap forward in an area known as in orbit satellite servicing.

Sophisticated sensor arrays, image processing, complex software, effective testing, guidance systems, and precise remote piloting, all played a role in MEVs success.

“SpaceLogistics’ pioneering RPOD technology for servicing in orbit is the catalyst for the bigger picture of humans building a responsible and enduring existence in orbit and beyond,” says Quenten Duden, Business Development and Operations, Civil and Space at SpaceLogistics. "We have proven technology that is a vital piece to the overall aspiration of a sustainable existence in space.”

"To exist in space, we need to learn to mine, manufacture, assemble, and operate in orbit and beyond,” Duden says.

Long term, the technology behind the MEV and other satellite servicing spacecraft could someday lead to machines programmed to build facilities in space for mining and manufacturing.

“To assemble large parts from small parts, we need to deliver a capability in orbit that allows us to maneuver without regret, assemble with precision and repeatability, and architect the future for affordable upgrades and long life,” says Duden, who serves SpaceLogistics as a mission architect.

You might say Northrop Grumman has a bit of experience in this arena. Its roots include designing and building the Lunar Module lander that took Apollo astronauts to the surface of the moon.

Now, the company leads an industry team supporting the James Webb Space Telescope (JWST)—history’s largest and most complex space observatory—now orbiting the sun.

Mining Asteroids

Asteroids are believed to contain large deposits of rare metals such as platinum and gold that potentially would be worth millions of dollars. They also might contain raw materials to manufacture rocket fuel.

Learning how to manufacture rocket fuel from raw materials in space could open the door to long-distance space travel, including space colonization, according to NASA studies.

Currently, every spacecraft must begin each mission with all the necessary fuel to complete the entire voyage. But what if rockets launching from Earth only needed enough fuel to achieve orbit? Think of the weight it would save. These rockets could fill up for the rest of the trip at an orbiting depot with fuel made from asteroids by autonomous spacecraft.

In fact, NASA has already been making small steps toward the dream of one day mining asteroids.

In 2020, the agency’s OSIRIS-REx spacecraft successfully landed on an asteroid, measuring about a third of a mile wide, called Bennu, located 200 million miles away. After collecting a sample, OSIRIS-REx began its return journey to Earth and is now on track to be the first U.S. mission to bring back an asteroid sample next year.

“The mission will develop important technologies for asteroid exploration that will benefit anyone interested in exploring or mining asteroids, whether it's NASA or a private company," said Dante Lauretta, a University of Arizona scientist working on the mission on NASA.gov.

OSIRIS-REx is still a long way from spacecraft that can reliably offer commercial asteroid mining services. But it’s the start of what could be a very long and fascinating journey.

Maintaining and Repairing Space Stations

Sophisticated satellites also could be engineered to maintain and repair space stations orbiting Earth or the moon.

NASA’s Artemis Program, which aims to return astronauts to the lunar surface, includes a proposal to build an outpost orbiting the moon. If built, the Lunar Gateway would serve as a way station for astronauts traveling to and from the moon as well as a staging point for deep space exploration. Initially, Gateway will be maintained, repaired, and inspected by a smart robotic system outfitted with mechanical arms. Perhaps someday, automated spacecraft could accomplish these tasks.

Assembling Satellites in Space

Thinking about space technology in the far future, experts have proposed the possibility of developing automated robot spacecraft that could build structures in Earth orbit, such as large satellites.

For example, the James Webb Space Telescope recently deployed in solar orbit had to be launched in one piece atop an Ariane 5 rocket. The huge observatory including its tennis-court sized sunshield was carefully folded into a compact shape to fit it into the rocket.

Scientists were worried that something might go wrong when the telescope’s huge solar array unfolded in space.

Although everything went as planned, those complex folding design requirements might have been avoided with the help of sophisticated automated spacecraft.

“Imagine if, instead of having to build the whole thing on Earth and do this very arcane stuff to fold it up and fit it into a rocket, what if you launched it in a bunch of pieces and assembled it on orbit?” says space policy expert Brian Weeden, director of program planning at Secure World Foundation. “There’s a whole bunch of opportunities there for future scientific instruments that could be far bigger than the James Webb—even if rockets stay the same size.”

LEGO-like Satellites

Machines that build things in space would be a long way off, but industry experts are talking about what technology it might require to get us there.

One idea involves constructing satellites made of standardized and easily changeable components—sort of like sophisticated LEGO building blocks. With this kind of design a sophisticated service satellite might be able to easily swap out broken or worn out components. Interchangeable components would make it possible to upgrade satellites or change their capabilities.

Engineers and operators could more easily switch or upgrade an orbiting satellite’s cameras for different missions, Weeden says. “Or you could swap out the antenna system or change the radio frequencies it operates on. There’s a lot of potential opportunity there. That’s the kind of technology being developed right now.”

Leading the Way

These aspirational ideas about mastering life in space are theoretical because satellite service is just now emerging as an industry. SpaceLogistics is one of several members of an organization called the Consortium for Execution of Rendezvous and Servicing Operations (CONFERS) that aims to foster communication among industry players, which might help the industry as a whole achieve important breakthroughs.

“It’s about setting industrial standards for space—for how we do RPOD, how we do refueling—trying to lead the way,” SpaceLogistics president Rob Hauge told FLYING. “On everything we’re doing, we’re trying to be cooperative.”

Supported by the Pentagon’s Defense Advanced Research Projects Agency (DARPA) and coordinated by the Secure World Foundation, other members include Airbus, Voyager Space, and Redwire Space. CONFERS goals include “building common understanding between developers, operators, customers, investors, insurers, and government policy makers.”

Harvesting Space Junk

CONFERS is also involved in industry projects aimed at developing autonomous spacecraft to clean up countless pieces of space junk orbiting Earth.

Space debris, which moves at speeds up to 17,500 mph, can potentially damage or even destroy satellites, space stations, and spacecraft. Debris especially poses a collision risk to satellites in low Earth orbit (LEO)—an area within about 1,200 sm above the planet.

Japan, the European Union, and most recently the United Kingdom have all announced programs aimed at demonstrating the ability to remove space debris in LEO, Weeden says. “When that happens, that will be very important.”

Space policy experts believe it might be possible one day to capture the most valuable space junk and harvest it for raw materials so it can be used again. But as Hauge says, “I think we’re a long way away.”

As far off as some of these ideas may be, portions of the initial technology are being developed now—baby steps in a longer journey toward a dream of mastering space.

Editor’s note: Jeremy Kariuki contributed to this report.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox

![United Airlines secures FAA approval for Starlink, with first commercial flights set for May. Starlink offers 50x faster internet, free for MileagePlus members. [Courtesy of United Airlines]](https://www.flyingmag.com/uploads/2025/03/UnitedAirlines_Starlink_Image.jpg?auto=webp&auto=webp&optimize=high&quality=70&width=1440)