DeltaHawk DHK180 Engine Heads To Production

The new piston engine has been in development for 15 years.

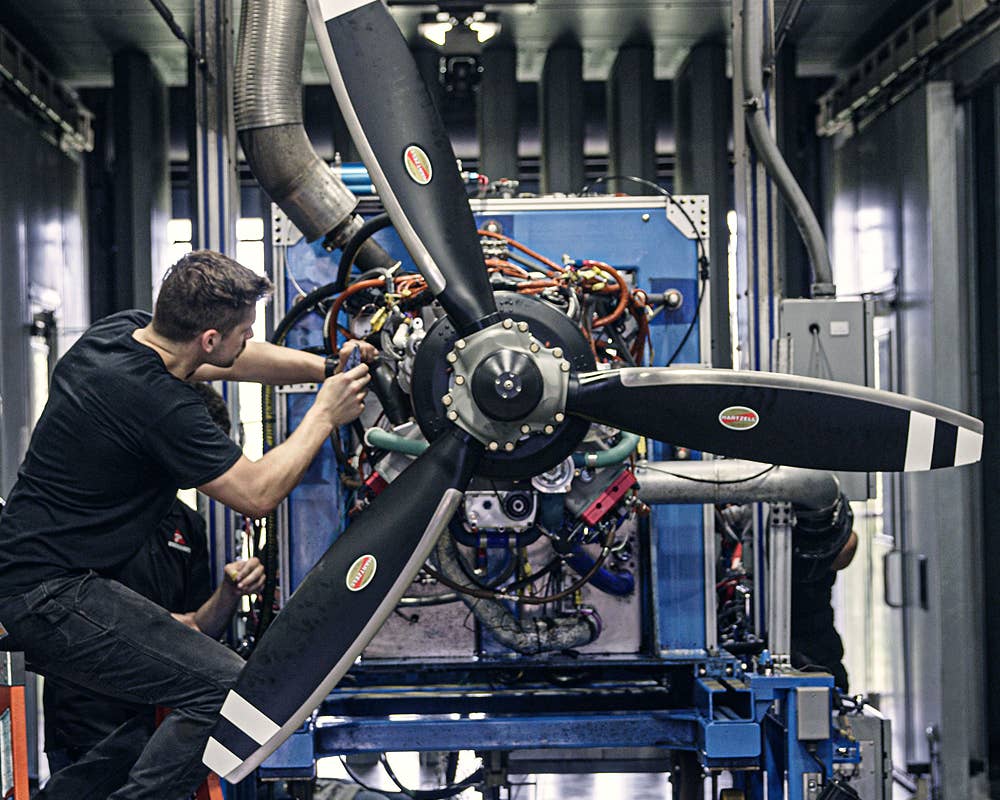

Having received FAA type certification of its revolutionary new DHK180 aircraft piston engine in May, DeltaHawk Engines is now ramping up production planning and finalizing sales and support activities in anticipation of initial customer deliveries in the first half of 2024. [Courtesy: DeltaHawk]

DeltaHawk Engines Inc.'s new DHK180 piston engine, which was FAA certified in May, is heading toward production, the company announced Monday at EAA AirVenture.

According to Dennis Webb, DeltaHawk director of marketing and certification, the new engine was approximately 15 years in development.

"It seemed like a long time in the industry. ITt seemed even longer to us," said Webb, noting that the Racine, Wisconsin-based company was determined to build an engine with the durability of a semitruck, and reliability worthy of the space program. "We chose to make it simple with direct drive rather than a gearbox. Simple is hard in engineering."

According to the company, the 180 hp DHK180 burns jet fuel and is" the first of a family of engines to come from DeltaHawk and offers ease of operation, high fuel efficiency, reduced maintenance, and superior altitude performance compared to traditional aircraft piston engines."

Company officials said the engine was designed to operate more cleanly and efficiently than those already on the market.

Chris Ruud, DeltaHawk CEO, pointed out the DHK180 is built from U.S.-made components.

"It is 100 percent manufactured in the United States in Racine, Wisconsin," said Ruud, who comes from an aviation family, and also noted that developments in engineering and technology have made the DHK180 possible. "Thirty to 50 years ago. this engine could not have been produced."

During the press conference at AirVenture in Oshkosh, Wisconsin, company officials explained that the engine is designed to operate on fuels other than 100LL and, as such, they have received "extraordinary interest in the new engine from a broad range of aircraft OEMs and experimental kit manufacturers, as well as individual pilots and commercial operators."

Webb added that the DHK180 was also recently chosen by NASA for its Subsonic Single Aft Engine project, known as SUSAN. The DHK180 also has been selected by Ampaire for a hybrid proof-of-concept aircraft.

What Happens Next?

DeltaHawk is in the process of preparing for engine production and commercial sales. This includes performing more endurance testing and flight evaluations in multiple aircraft.

Webb said the company went beyond the FAA's requirement for endurance testing for engine certification, and DeltaHawk has a factory warranty program that will cover 24 months or 2,000 hours, whichever comes first.

The new warranty can also be extended to 36 months or 2,400 hours if an operator agrees to provide timely engine-monitoring data and oil analysis—an industry-leading option, according to the company.

In addition, the company's engine deliveries for both certified and experimental aircraft will include firewall-forward installation packages for specific aircraft. Packages for selected aircraft are now under development, and final pricing will be announced soon. The company is also actively seeking industry partners with engine installation STC experience to augment DeltaHawk's capabilities.

Initial deliveries of customer engines are planned for the first half of 2024.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox