Department of Defense Invests in Hypersonic Testing Upgrades at Arnold Air Force Base

Additional staffing will allow the high-temperature laboratory to operate longer hours as demand for testing is expected to increase in the year ahead.

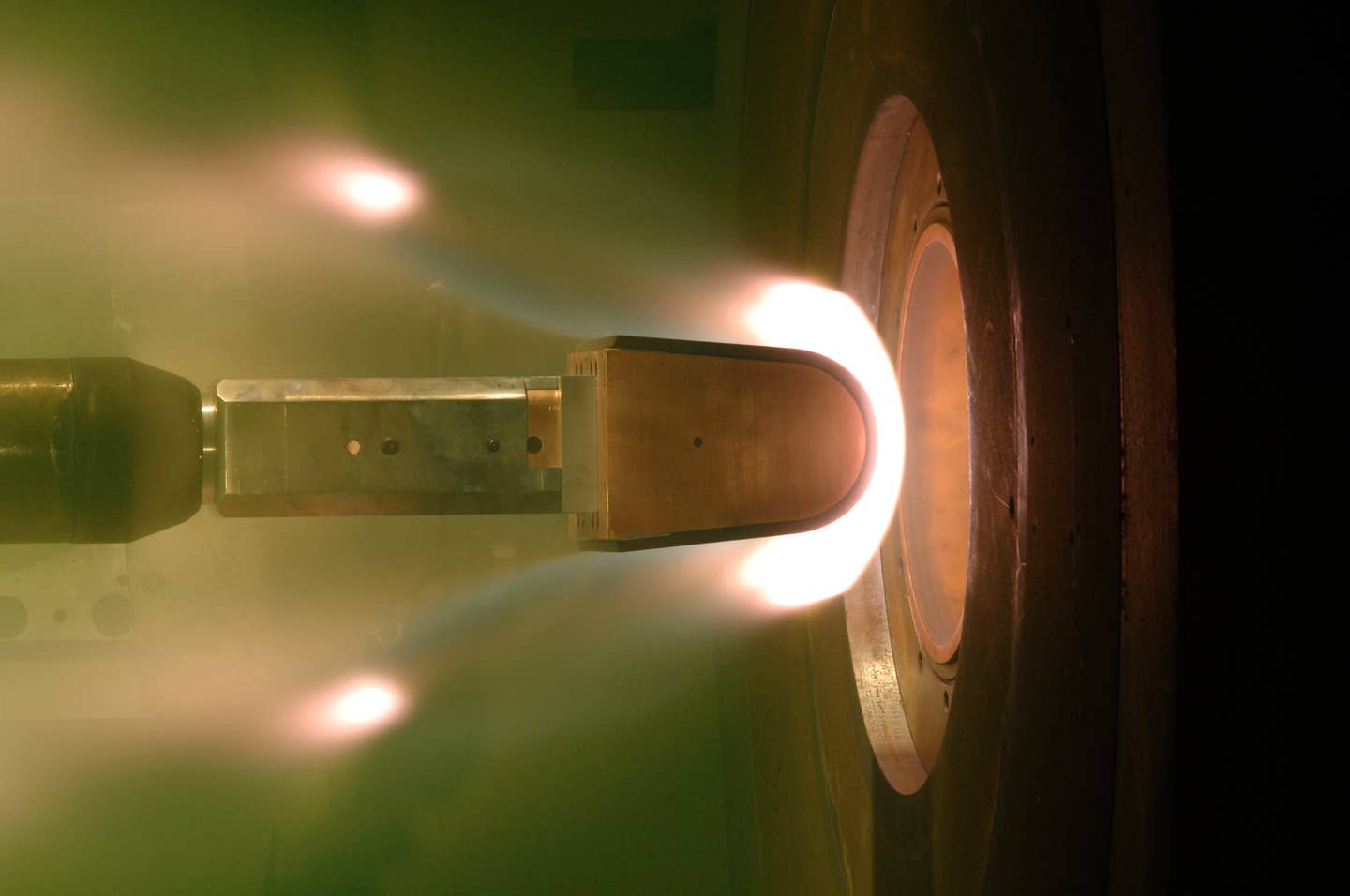

A carbon-carbon leading edge undergoes testing in the arc jet test cell H-2. [Courtesy: U.S. Air Force]

Arnold Air Force Base’s space testing branch is ramping up testing throughput capacity in anticipation of an increase in demand for hypersonic systems testing in the coming year, it announced.

The move comes as the Arnold Engineering Development Complex (AEDC) at the air base in Tullahoma, Tennessee, is also modernizing testing capacity for next generation turbine engines for military aircraft.

According to AEDC, the facility has received $2.35 million from the U.S. Department of Defense’s Test Resource Management Center (TRMC) to support staffing increases for high-temperature materials characterization and evaluation capability testing for hypersonic systems, as well as needed supplies for hypervelocity flyout, impact and lethality ground test and evaluation.

At least $850,000 of funding has been spent since 2020 on hiring five new engineers and 10 craftspeople for high-temperature lab operations that include test runs, facility maintenance and test buildup, the facility said earlier this week in a statement.

“With the additional staff, the High-Temperature Laboratory, composed of three arc heaters, can be operated 16 hours a day, 5 days a week, with the ability to surge to longer operations when the test schedule requires,” the AEDC statement said.

The new personnel are needed because demand for hypersonic testing is increasing.

“With the growth in personnel, test frequency has increased from 77 runs in fiscal year 2020 to a forecasted workload of 116 runs in fiscal year 2022,” Frank Wonder, Arcs Section chief, said in a statement. “Additional TRMC-funded improvements have the potential to increase test throughput at the arcs facility to 150 runs per year in fiscal year 2023 and beyond.”

Hypersonic testing at the facility involves high-temperature material testing with arc heaters that simulate the aerodynamic heating and mid-to-high shear pressures that occur during hypersonic flight and re-entry as a way to characterize and evaluate erosion of thermal protective materials and systems. The form of testing is crucial for developing hypersonic weapon systems and re-entry vehicles, AEDC said.

“Being on the cutting edge of hypersonic weapons system development is motivating to young engineers. They want to come work here,” Wonder said. “Rather than just serving as facilitators in an ‘air Rent-a-Center,’ they are providing acquisition programs with actionable information that positively impacts the weapon systems development process.”

At least $1.5 million of funding was also spent for supplies supporting hypervelocity flyout, impact and lethality ground test and evaluation at Range G, a ballistic range at the air base that evaluates aerodynamics and impact lethality of hypervelocity and high-speed systems.

“These improvements and modernizations increase test turnaround and eliminate single-point-of failure items that are aging and increasingly likely to cause delays,” Shana Morris, AEDC project management support, said in a statement.

In addition to accommodating the predicted surge in demand, the investments are already reducing downtime and improving facility performance, according to officials.

“The National Defense Strategy has multiple objectives that require the support of AEDC’s Hypervelocity Ranges in support of development and acquisition programs,” said Jonathan Carroll, chief of the Ranges Section. “Recent years have seen an increase in customer demand, as well as multiple capability reactivations in support of test customer requirements. Meeting these surging demands, while continuing to deliver unique test data will be critical to provide decision ready information to program offices and requirements owners.”

In late November, AEDC announced it was also investing in facility upgrades for testing of U.S. Air Force next-generation aircraft.

The engine test facility, which has tested turbine engines for the majority of the Department of Defense's cruise missiles and fighter and bomber aircraft for the past six decades, announced November 24 that it is restoring and modernizing two altitude test cells of the Engine Test Facility that simulate flight conditions.

As part of the Next Generation Turbine Engine Test Capability Project, the two 28-foot diameter test cells were restored—one with the ability to achieve Mach 3 and operate at 600 degrees Fahrenheit, and the second with the ability to achieve Mach 2.3 at 350 degrees Fahrenheit.

The capital investments are necessary to address deficiencies that existed in the test cells before next-generation propulsion systems emerge, according to one facility official.

“The next-generation turbine engines may incorporate new technologies that will require test facilities to provide higher inlet temperatures and potentially up to 50 percent more mass flow than the largest fighter engine in the fleet,” Rick Hutchings, technical lead for the AEDC Future Capabilities Branch, said in a statement. “There are no other test facilities or test cells in the Major Range and Test Facility Bases or the country with the required capability or expertise to test these new engines, qualify them for flight release and assure they are suitable to operate in the entire flight envelope than what exists at AEDC.”

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox