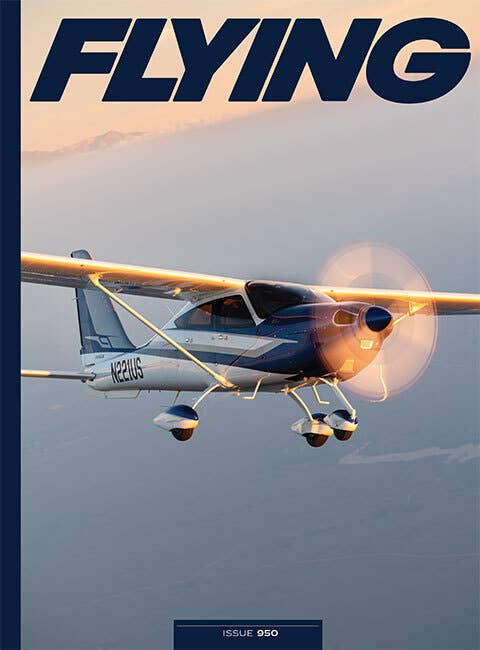

The vibrant display of a new JPI EDM 830 engine monitor. [Les Abend]

Only a handful of circumstances in my airline life required a return to the gate or immediate return to the airport. Never did I divert twice in one day. But on one particular trip from Flagler Executive Airport (KFIN) in Florida to Asheville Regional Airport (KAVL) in North Carolina, my wife and I unwillingly filled that square.

As we climbed into the faded-jeans color of a perfect Florida sky, I glanced at the vibrant display of a new JPI EDM 830 engine monitor. The No. 1 cylinder was indicating a steadily increasing cylinder head temperature (CHT). All other parameters were normal. I hoped the temperature would stabilize. It didn’t.

If you're not already a subscriber, what are you waiting for? Subscribe today to get the issue as soon as it is released in either Print or Digital formats.

Subscribe NowWith the CHT approaching 400 degrees, I was concerned but not surprised, a sentiment verbalized to my wife. Fortunately, she’s never been a nail-biter. Reaching an altitude of 1,500 feet msl, I advised Daytona Approach Control that we would require a return to the airport. The response was immediate: “Do you require assistance?”

In my best airline pilot voice, I replied, “Negative.” This statement elicited an instruction for a heading and a climb, and to expect vectors for a visual approach. My primary goal was to retard the throttle, so as to prevent the CHT from increasing further. A turn and a climb wouldn’t be helpful.

Considering the CAVU weather, the problem was solved by canceling our IFR flight plan. I contacted KFIN tower, advising that we were entering a downwind leg. The approach and landing were accomplished without issues. I taxied to the maintenance shop with a wary eye on the No. 1 CHT. Keith, the mechanic who had spent countless hours meticulously installing the theoretical “plug-and-play” JPI, already anticipated my arrival. He greeted us under the open hangar door with his standard affable grin.

The day prior I had strategically dodged a line of early morning rain showers and flown to Baker Aviation at New Smyrna Beach Airport (KEVB) with the hope that a box of locally made donuts on a Monday could persuade the owner to have one of his avionics techs fix a problem I had created on the Arrow’s Garmin GNS 430W as a result of the JPI install.

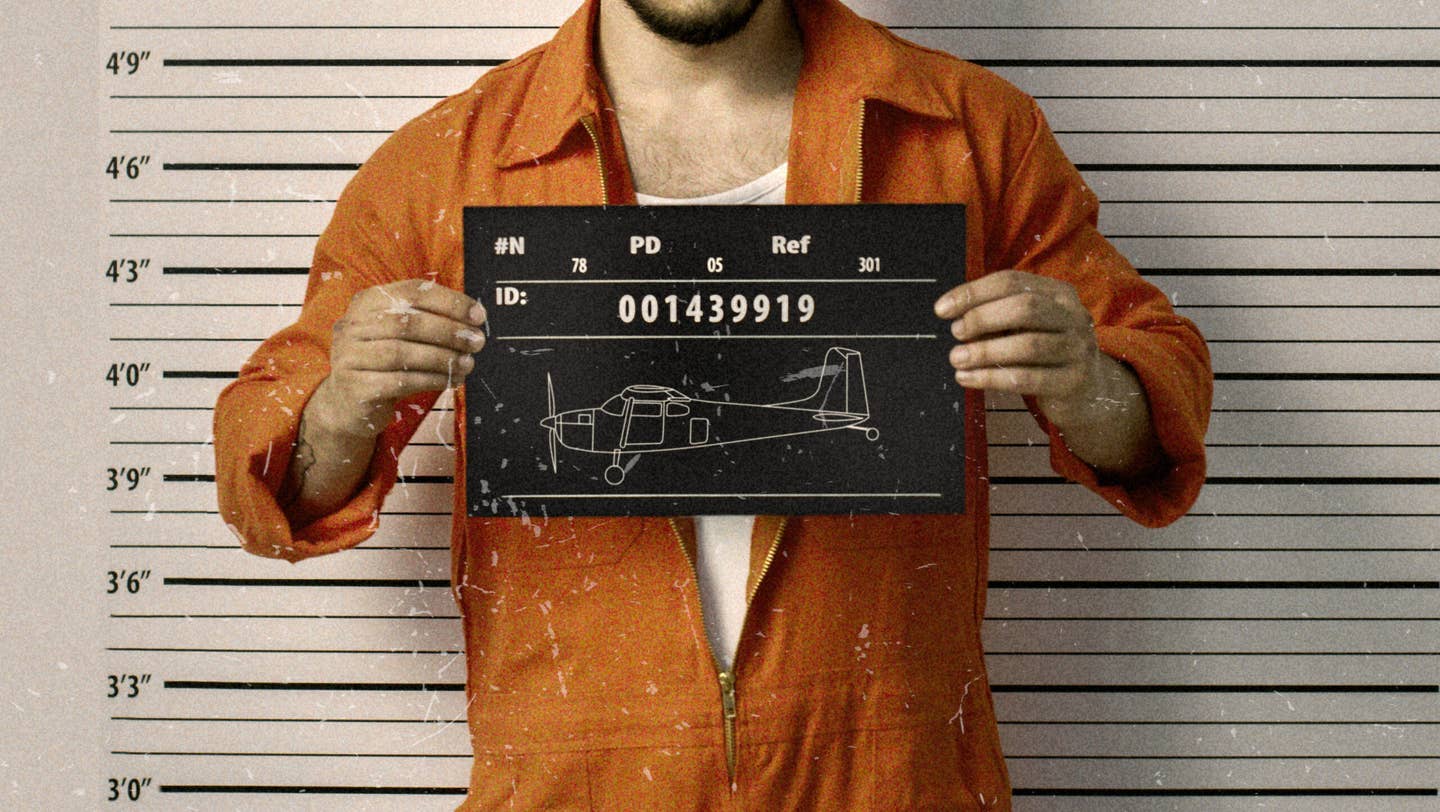

In an attempt to solve a fuel communication issue between the GPS and the new JPI, I entered the sacrosanct 430’s initialization mode. Forgive me, for I have sinned. Thinking it to be a simple matter of selecting the correct entries of input/output, I armed myself with instructions from the 430 manual, the JPI manual, and some internet info. I proceeded to obliterate the original setup.

Not only did I accomplish the task of eliminating the majority of communication to and from the JPI, but it appeared that ADS-B info linked to the GPS was no longer available. A smart person would have taken a photo of the 430 screen before starting down the rabbit hole, but I wasn’t that person. Thus, a trip to the sympathetic heroes at Baker Aviation. Thankfully, I did bring my maintenance documentation, which assisted the technician with the initial restoration process.

After my self-inflicted destruction was repaired, I launched skyward toward home, relieved that our trip to Asheville the next day was no longer in jeopardy. But alas, the No. 1 CHT began to increase. The only solution was to cruise over the coastline at reduced power.

Upon touchdown at Flagler, I taxied directly to the maintenance shop. With my description of a slow, steady temperature climb and no erratic indication, Keith began a methodical troubleshooting process. Fuel injector check. Induction leak check. Nada. An engine run-up was conducted. No issues. Hmm.

Which brought us to the engine run-up on the morning of the trip. The No. 1 CHT was higher than the other cylinders but not significantly so. In VFR weather, it was worth a try that nothing could go wrong. Well, chalk one up for hope not being a good strategy. In any case, the only real cause was most likely a bad CHT probe. Keith swapped probes with the No. 2 cylinder.

Two hours after our original departure time, we repeated our efforts to begin the journey to Asheville. As predicted, the CHT problem transferred itself to the No. 2 cylinder.

Fortunately for my airline pilot sensitivities in exceeding limits, the cooler temperatures at cruise altitude didn’t manifest into a flashing warning on the JPI display. That said, I incorporated the JPI into my instrument scan.

For those that read the No. 937 issue’s “Jumpseat,” the No. 3 cylinder decided to self-destruct during a climbout from Waycross, Georgia, (KAYS) in January. As a result of the cylinder’s replacement, the break-in period was still in progress, with most shops recommending an operation at 75 percent power. Because of the power setting, the fuel consumption was higher on our trip to Asheville, notwithstanding a headwind component that averaged around 30 knots—greater than the original forecast.

- READ MORE: Engine Troubleshooting in Double Time

Although we would have legal IFR fuel plus some upon touchdown, watching the needles move closer toward the left side of the gauge was not comfortable. It was an exceptional VFR day, so nothing could go wrong.

Approximately 20 minutes from KAVL, about the time the northwest winds were roiling off the Blue Ridge Mountains and bringing some unpleasant moderate chop, we were issued holding instructions over a fix on the approach course to Runway 35. Why? A disabled airplane on the runway. Great.

I inquired as to an estimate for reinstating the runway and received a definitive “no idea.” Envisioning an NTSB report with my name on it, I declared “minimum fuel,” conveying that two turns in the holding pattern would be our limit. Although my original plan was a diversion airport 30 miles to the east, Hendersonville Airport (0A7) was almost directly below us.

One and a half circles later, and a vector away from a Cessna Citation holding below us, we entered the 0A7 traffic pattern, 9.5 miles from the approach end of Asheville’s Runway 35. Landing on a 3,000-foot runway with tall trees on both ends, we touched down on pavement that seemed to just fit the Arrow’s wheelbase.

An accommodating airport volunteer, who was looking for an excuse to get off the mowing tractor, returned from another end of the field with a van that took us to the restrooms of an aviation museum jammed with incredible airplanes of all vintages. Wishing I had more time to spend—my wife not so much—we returned to our airplane.

With Hendersonville no longer having fuel available, I had called the Asheville Tower directly in order to determine the runway status and when it would be optimal to launch and not suffer the angst of delaying vectors. Twenty minutes later, we were airborne. The radar contact confirmation and clearance to land was given by the approach controller in almost the same sentence. Flight time: five minutes.

As fate would have it, the disabled airplane had been flown by one of the participants attending the same conference, the primary purpose of our trip. A main gear tire on his Columbia decided to go flat on rollout.

Two diversions in one day. No problem.

This column first appeared in the August 2023/Issue 940 print edition of FLYING.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox