An Ode to Aircraft Mechanics

To say times have changed in regard to aircraft maintenance would be an understatement.

Unearthing memories of aircraft mechanics I’ve known (the good, not-so-good, and downright bad), I guess I’ll begin with the first I ever encountered—60-some years ago.

Those guys are gone now, but the T-hangars on the south line at Cincinnati’s Lunken Airport (KLUK) where they worked are still there, close to where that little Ercoupe that my sister Mary and I came to fly was roosting in the grass. N341 (we should have kept the number) had been generously loaned to us by a friend who hadn’t flown it in some time. It needed an annual inspection, which Carl Garlough and his two helpers did, as well as repairing a few things like a hole in the gas tank before we took to the skies.

If you're not already a subscriber, what are you waiting for? Subscribe today to get the issue as soon as it is released in either Print or Digital formats.

Subscribe NowCarl was an amiable, sort of fatherly guy, probably trained in the military, who always had a pipe clamped between his teeth. And the man who took me aside and explained I might stop bragging about being a member of the “Mile High Club.” My dastardly instructor, Larry Whitesell, announced my prestigious status after we coaxed the little airplane (with a “sick 75”) above 5,000 feet. Naturally, I bragged about it but didn’t understand the reaction of the old guys around the airport who knew there was no way that could happen in an Ercoupe.

Carl was a good mechanic but also kept Tom Noonan’s airplanes running, although “TV Tom” had less than a sterling reputation with customers, creditors, insurance companies, and the FAA. Working with him in his shop was a nice, competent mechanic named Henry, who I would learn was a periodic alcoholic—on his game for weeks at a time only to disappear. Henry always showed up days or weeks later with the shakes and often badly beaten up. But Carl, bless him, helped him along. Another young guy, whose name I can’t remember, was a newly certificated “A&E” (in those days). He was maybe a little sweet on Mary, but I reminded her the only aircraft mechanic school in the state of Ohio, in those days, was the Chillicothe Reformatory.

- READ MORE: Perusing Some Old Logbooks

Those guys kept the Ercoupe running while Mary and I got out private licenses. And Carl even used a bolt cutter on the chain my dad had wrapped around the prop of the Ercoupe sitting out in the grass. He was determined to keep me grounded while he and my mom were away for a few weeks because he thought I was cutting too many classes at college to go to the airport. Before my parents even knew I was taking lessons, I had forged his signature on the permission slip required in those days for students under 21 to solo. Anyway, somebody hooked the chain back up before they got back.

Oh, my, how things have changed. There are no “small airplane” shops on Lunken Airport these days—at least ones that last. I fly to a smaller airport nearby for maintenance and annuals. In an emergency, Mark Day from Blue Ash Aircraft Service at Lebanon will drive down to do the repair. Lots of guys use freelance A&Ps who arrive in pickup trucks and pull the annuals in their (or a friend’s) T-hangar. And lots do the annuals themselves, paying a friendly IA to sign off their work. Thank the Lord, I’m not mechanically inclined. An old boyfriend—a toolmaker with an IA—used to tell me, “Machinery doesn’t love you.”

Small shops are increasingly rare at large airports. It’s too expensive and new A&Ps can get better-paying, more secure jobs with the airlines or large corporate operators. A friend took his Cessna 182 to the shop at a large, local FBO that caters to bizjets. It charged him for 10 hours of work to change the oil.

But it certainly wasn’t always that way through the 1970s when Lunken had at least two large, full-service, FBOs that began in the ’30s. Cincinnati Aircraft, a Cessna dealer, occupied two of the three large brick hangars built in the ’20s for the Embry-Riddle Company. Queen City Flying Service, a Beech dealer in Hangar 3, was always a “posh” operation that catered to people with more money than we had. The offices were up a spiral staircase that led you into something right out of a ’30s or ’40s movie with art deco furniture and fixtures, private inner-sanctum offices, and a woman at the front desk. The parties and liaisons that went in Hangar 3 were legendary but, in fairness, the airplanes, pilots, instructors, and mechanics at both operations were top-notch.

Back in the day, I confess we’d send the Cub logbooks to an IA friend who signed them off for $100. Another guy worked for years as a pilot and mechanic with phony, forged certificates.

But you have to watch out even for the good guys. Flying your airplane after an annual is kind of a risky process, so do a good preflight check and stay over at the field until you’re sure everything works as it should.

Barry Schiff tells me he flew a Tri-Pacer (I said, “Shame on you.”) in California after annual. There was no problem in flight because you hardly use the rudder pedals anyway. But turning into the FBO after landing, there were curious “crunching noises.” It seems somebody had allowed a metal E6B computer to migrate back in the tail.

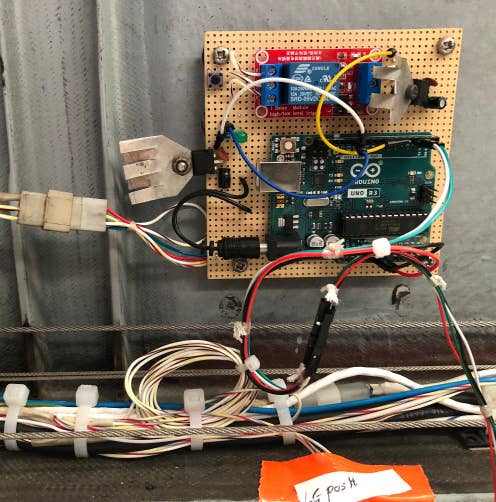

A corporate pilot for a squeaky-clean, very large company told me a mechanic had left a wrench inside the engine of a G3 with devastating results. I think he was relegated to making soap. Another lost all power (IFR) when flying a Cessna 182 home. Two G-5s had been installed by a radio shop, but the crankcase breather port was blocked by a plastic cap with oil spewing out of the underside of the engine.

I found a large black Maglite jammed behind the rudder pedals and another very conscientious mechanic wouldn’t let me fly again until he drove to Cincinnati to retrieve a hand mirror from the tail section.

You’d be surprised at the number of things that are FAA- and manufacturer-approved temporary repairs—some involving “speed tape’” (if you can afford $700 a roll). It’s said that you could stick one end of the roll onto the hood of your car and pull it with the other end.

Look at the FAA publication Maintenance Aspects of Owning Your Own Airplane but, remember, you gotta know what you’re doing.

This column first appeared in the July/August Issue 949 of the FLYING print edition.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox