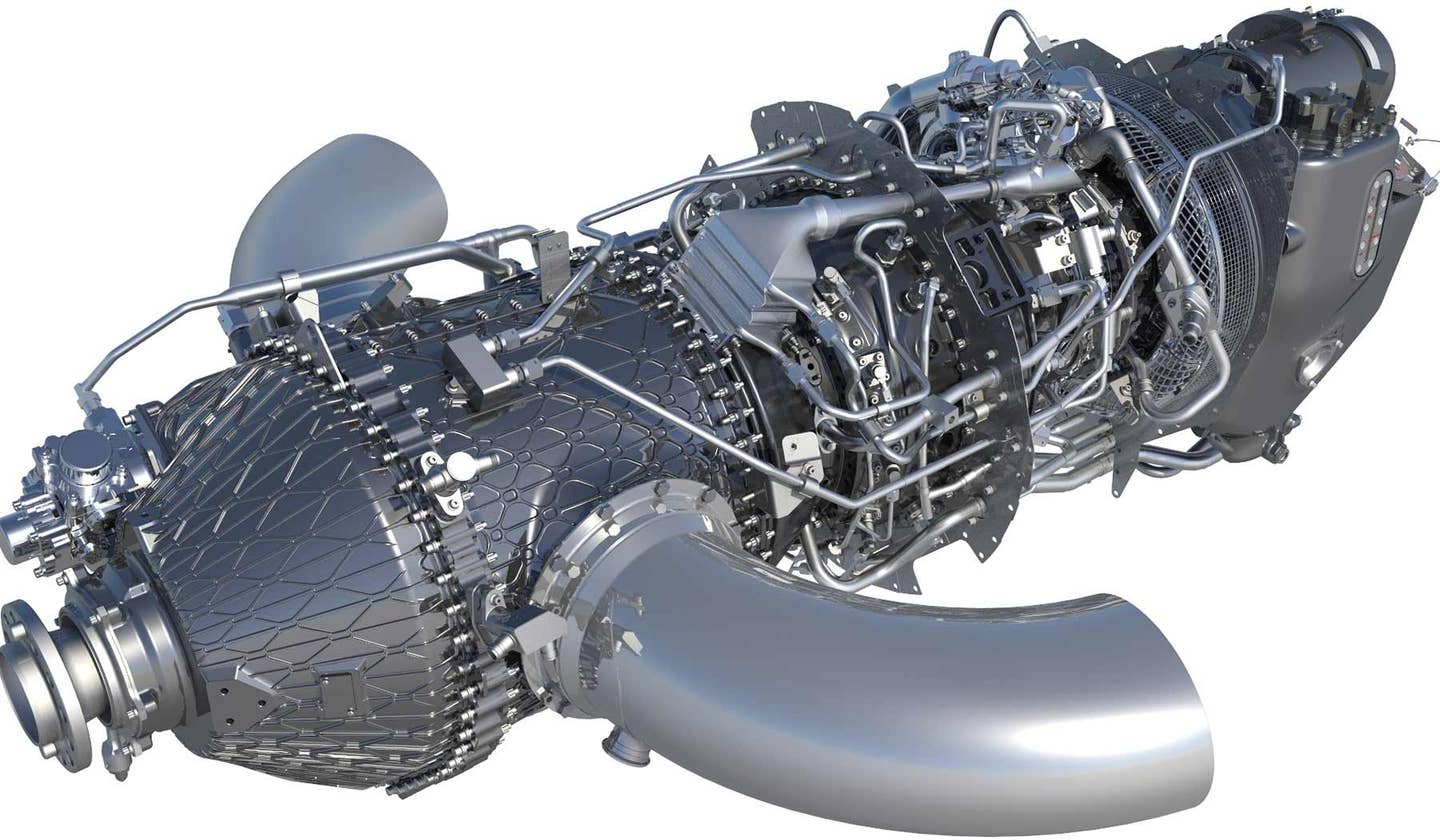

GE Aviation completed the first test run of its new Advanced Turboprop engine, which incorporates more 3-D-printed components than any production engine in aviation history. GE

GE Aviation completed the first test run of its new Advanced Turboprop engine, a clean-sheet design that will power Cessna’s forthcoming Denali business turboprop and go head to head with Pratt & Whitney’s venerable PT6A engine family.

GE says the Advanced Turboprop incorporates more 3-D-printed components than any production engine in aviation history, comprising 35 percent of the turboprop’s total part count. Specifically, GE noted that a total of 855 conventionally manufactured parts has been reduced to 12 additive parts, including sumps, bearing housings, frames, exhaust case, combustor liner, heat exchangers and stationary flow path components.

The milestone for GE Aviation keeps the 1,240 shp engine on pace for first test flight of the Denali late this year.

"With the engine run and most of the individual component testing completed, early indications show that we will meet or exceed all the performance numbers we have quoted for the engine," said Paul Corkery, general manager for GE Aviation Turboprops.

The Advanced Turboprop engine, intended to serve the 1,000 to 1,600 shp engine market, is designed and manufactured by GE’s growing European subsidiaries. Avio Aero in Italy designed the engine, and it was test run for the first time on December 22 in the Czech Republic at facilities owned by the former Walter Aircraft Engines, which GE acquired in 2008.

In development since 2015, GE Aviation reports it has committed more than $400 million to the engine program.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox