||| |---|---| | | | The morning was still clear and cool when I pushed the Cheetah's throttle forward and lifted off from Runway one-four at Santa Rosa. At first it was a takeoff like any other I'd had with the plane, and I let out a sigh of relief at finally being off on our trip across the country. I turned crosswind and was climbing through about 1,200 feet when suddenly the engine made a unnatural, rumbling "BLAU-BLAU-BLUM" noise and a shudder ran through the airframe. For a single, heart-stopping moment, I thought I'd lost power completely. But, no, the engine seemed to have just stumbled and then regained its footing again.

I didn't care. Whatever had happened, it wasn't my imagination, and it wasn't right. I called the tower and in a surprisingly calm voice told the controller I'd had a change in plan, my engine had just made a funny noise and I wanted an immediate return to the airport. Two other pilots in the pattern, bless their souls, called and volunteered to clear out of the way to give me priority, and a couple of minutes later my wheels touched down on pavement again.

I taxied over to the hangar area, hoping to find a mechanic who could take a look at the plane. But as I shut down I remembered that all the mechanics I knew were out of town for the weekend at an airshow. I opened the cowling and looked for some kind of trouble, but whatever was wrong was not patently obvious. For several long minutes I just stood next to the plane, not willing to take off again but totally clueless as to what to do next.

In desperation, I finally called my friend and former Cessna 120 partner, Jim Dale, who also happens to be one of the best mechanics I know. He was at an airshow himself, but thanks to the cellular era in which we now live, I got hold of him and he was soon trying to troubleshoot my engine from 1,500 miles away. It was, shall we say, a somewhat frustrating experience for both of us.

"Have you checked the gascolator?" he asked. "I don't think I have one, Jim." "It would be near the bottom of the engine, connected to the fuel lines." "Which ones are the fuel lines?" I could hear his exasperated exhalation as airshow jet noise filled my ear. "They're usually coated in red. But not always. Find the fuel pump." "Where's the fuel pump?"

And so it went, for about 25 minutes. If I'd been a little less stressed or worried, I might even have been vaguely amused at the image of a woman standing on a deserted airport ramp, fuel system schematic in hand, cell phone wedged between her ear and shoulder, trying to learn and troubleshoot the parts of her engine from a mechanic half a continent away. At the time, however, my sense of humor was buried even deeper than the carburetor fuel control valves.

Jim finally concluded that water in the fuel was the most plausible explanation for my trouble, even though I hadn't found anything in the fuel I'd drained before or after the flight. "It might have already run through the engine," Jim said. "Take it up and just orbit the field for 10 or 15 minutes or so, and if it does OK, then come back, fuel up, get a bite to eat and launch."

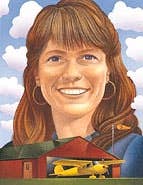

As I prepared to climb back in the airplane, I found myself looking at the Cheetah in a new and uncomfortable light. In the 300-plus hours I'd flown her, we'd been through a lot, but she'd never let me down. In a sense, I looked at us as friends, as much as a woman and a machine can have that kind of relationship. I'd come to trust her. It was not a blind trust, of course, for I knew that mechanical parts could always fail. But the main selling point on this plane when I bought it was its 85-hour, factory-overhauled engine, and aside from some fouling of the spark plugs, it had never given me a minute's trouble.

I bolstered myself with the thought of momentary and safely dispersed water trouble and took off again. I circled the field for 15 minutes, and all was well. Somewhat reassured, I pulled back the power to re-enter the pattern.

"BLAU-BLAU-BLUM!" Another shudder ran through the airframe as the engine stumbled again, then continued on. Enough was enough. I landed, parked the plane, and called around until I found a mechanic who could look at it. The mechanic drained fuel, drained the carburetor, checked lines, plugs, compression and connections but could find nothing wrong. He even went around the patch a couple of times with me, but the engine behaved perfectly. "Probably just some water in the fuel, gone now," he finally shrugged, proclaiming the plane good to go.

The next morning I set out again, but without the calm relief of the day before. This time I was at 4,000 feet, about to leave the valley for the rugged mountain ridgelines, when the engine stumbled again. I returned and circled over the field while I considered my options. I could land again, but I'd already had a mechanic check everything that apparently could be checked, and he'd found nothing wrong. The engine seemed to be running OK again. I decided to climb over the field to 9,500 feet. If the engine kept running well I'd then head out, hoping that if the stumbles continued they would be momentary, and that my altitude would allow me to glide to a safe landing spot if they weren't.

My flight through the Sierras to Bend, Oregon, turned out to be uneventful, but it was a long way from relaxing. Like an eagle searching for prey, I kept a constant lookout for potential landing sites through the mountain passes, listening vigilantly for the tiniest change in engine sound. "Engines often start talking to you before they quit, so pay attention," Jim used to say. But it's not quite that simple, I realized with frustration as I looked down at the scanty landing sites south of Mount Shasta. My engine was unquestionably talking to me. The problem was, I didn't understand what it was saying.

In Bend, Mike Schrader, who is not only the national sales manager for Lancair but also an IA mechanic, put a new load of Exxon Elite oil with anti-scuffing additive in the plane, on the theory that my problem might not be water, but a sticking valve. For two whole legs, the engine ran fine. Then, in the jagged mountains north of Idaho Falls, it stumbled again. Then again, coming into Billings, Montana.

As the stumbles continued, I found myself moving from concerned parent to insecure lover. My first thought was to worry about what was wrong with the Cheetah; to ask her to please tell me what was wrong so I could understand what to do to make it better. But as the journey progressed, I began to worry more about myself than my plane. I was flying over mountains and the hostile, forest-choked lands of the northern boundary waters and Canada, and I no longer trusted my engine. I climbed high, tried to keep a potential landing spot in sight at all times, and waited nervously and fearfully for her to betray me again.

How could this be, I wondered? How could the plane I'd spent so much time with now feel like an untrustworthy stranger? Could the bond of all those good hours, of the partnership we'd known, be so easily shaken? I remembered what an air race pilot friend of mine had said before I'd taken the Cheetah across the country the first time last year. We'd been talking about potential emergency situations and off-airport landing techniques, and he'd told me in a stern tone of voice, "Just remember. If your engine quits, your plane has just betrayed you. It is no longer a friend or something worth saving. Don't worry about finding a landing spot that will spare the plane. Trash the airplane if you have to. Rip the gear out, tear the wings off. Just worry about saving yourself."

My Cheetah had not betrayed me entirely, of course. The engine had not quit; my lover had not yet had a full-fledged affair with another. But my engine had stumbled, let me down. The lover had fallen off the wagon for a brief interlude or night. And having proven it was capable of indiscretion, I found it difficult to trust that the indiscretion would not repeat itself or lead to a bigger betrayal.

The truth is, I realized once again, that any kind of trust is a tenuous connection in need of constant renewal; something easily broken and difficult to rebuild. Trusting a machine or human, friend or lover, with the life or heart you hold dear is a tricky and frightening endeavor. It requires more than a bit of courage because it entails a leap of faith. We can think out our choices carefully-try to preflight well. But at some point we have to just hope that our trust is well placed and jump, or we will never be able to fly.

There are those, of course, who are so afraid of having their trust betrayed and the fall that might follow that they stay on the ground forever with their hearts or selves safely locked away. I understand their fear. But I hope I maintain enough courage never to become one of them.

Four mechanics and a serious, heart-to-heart talk with Lycoming later, my engine problem was finally diagnosed as a sticking valve. The folks at Textron-Lycoming were great, offering tools and advice to help troubleshoot the problem with the least amount of headache and cost. I have had the best people at Lycoming assure me that the engine should run fine now. I have had the FAA-certified mechanics who performed the work suggested by Lycoming assure me that the plane is now safe and good to go.

But I look at my beloved Cheetah sitting on the ramp, and I realize that we still have some rebuilding to do. For it will take more than outsiders' assurances for me to trust her again. As with any other relationship where the trust gets a little shaky, it will take a little time.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox