A recent recurrent training period in human factors class inspired Les Abend to recall some memorable moments from his airline career. Philippe de Kemmeter

During a recent recurrent training period in our human factors class, the check airman instructor asked for a show of hands for those who had experienced an engine failure during their careers at the airline. The classroom consisted of about 30 well-seasoned pilots. Barely a quarter of the class raised their hands. The same question was asked for anyone who had experienced more than one engine failure. I scanned the room. My hand was the only one raised. Really?

The instructor’s question was a prelude to video re-creations of some real-life emergency events experienced by fellow crewmembers that we were about to watch and evaluate. I had never really dwelt on my engine failure experiences, the memory of the adrenalin rush long since forgotten.

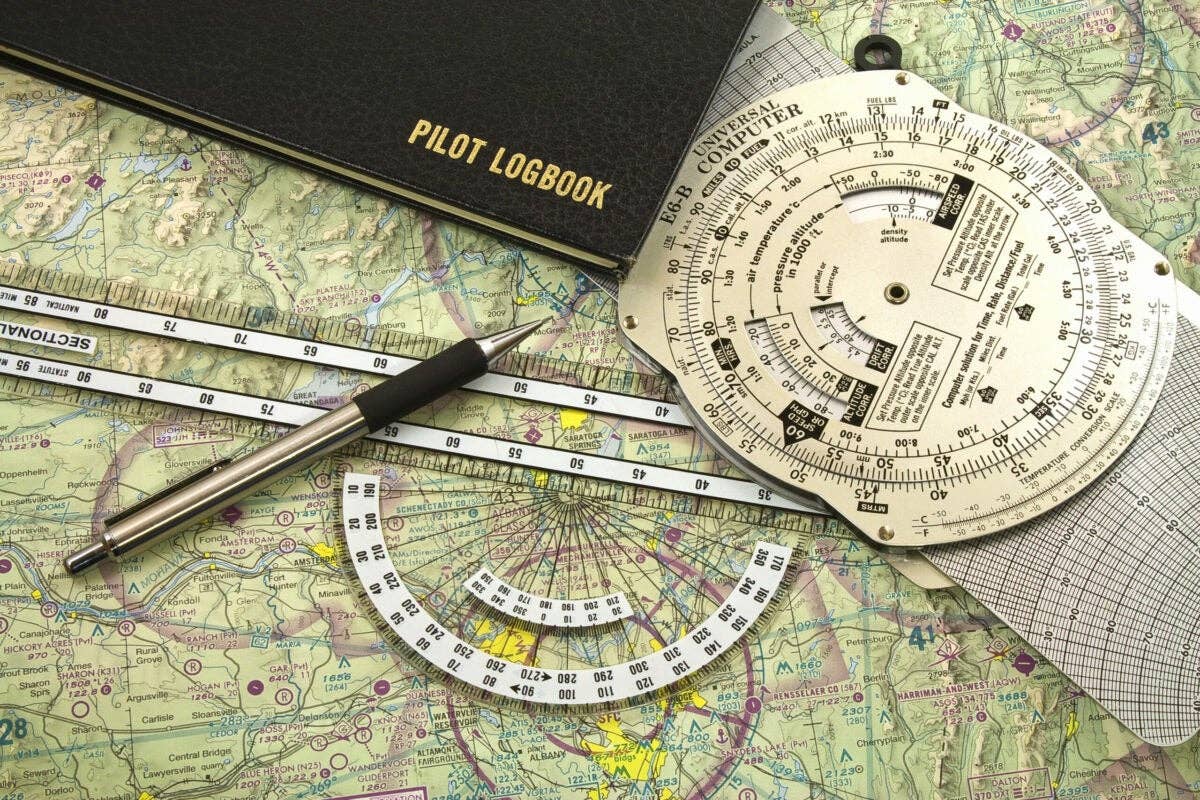

Many years ago, at a commuter airline based in New Jersey, my copilot and I were presented with a textbook decision. I had just leveled our 19-passenger Twin Otter at a cruise altitude of 4,500 feet after departing the now-defunct Bader Field in Atlantic City. (Yes, we oftentimes flew VFR.) Our destination was Philadelphia, the airline’s bread-and-butter route.

A glance at the right-engine oil pressure gauge indicated something was out of place. The needle was pointing at a position just above zero. Not good. I performed the typical pilot ritual of rapping a knuckle on the glass. No movement. My copilot offered an expletive in acknowledgment of the problem. A quick study of the cowl that covered the PT6 engine showed no evidence of goopy brown oil streaks.

A brief discussion ensued, with both of us agreeing that the low oil pressure was most likely the result of a faulty indication. Even at the ripe old age of 25, I knew only one decision was the prudent course of action. Shut the engine down. I reached up and pulled the right throttle back to idle, confirmed with my copilot that I had a hand on the correct fuel lever, slid the control to cutoff and then feathered the prop.

We continued with the appropriate checklist, declared an emergency, advised our passengers and requested a return to Atlantic City’s international airport, which had the longer runways. Our landing was uneventful except for my copilot’s occasional disconcerting glance out his window at mostly unmoving propeller blades. The eventual diagnosis: a faulty oil pressure sensor.

On a humorous note, after the crash-fire-rescue team finished its brief inquiries, we remembered another issue. Our day had already involved six legs, with little downtime for a food break. A bag of fresh cherries had become our only sustenance. Occasionally, we misfired our pits into scattered areas of the cockpit, our intention to clean up later. My copilot and I attempted to locate the errant debris before our mechanics discovered the in-flight activity. Priorities.

The next event occurred with my current employer. I had been a 767 copilot for approximately one year. We were flying our first leg from La Guardia to Chicago. Capt. Jack and I had just placed the crew breakfast trays on our laps. I was about to plunge a fork into something yellow that resembled an omelet when we heard the staccato beep of an alert.

Jack glanced at the overhead panel, noticed an amber light illuminated on a switch and declared with a slight inflection, “I think we lost the right generator.”

I looked forward and scanned a handful of amber messages that were beginning to populate on the engine instrument and crew alerting system screen. The airplane didn’t feel like it was flying normally. I looked at a series of gauge indications, all of them in the process of winding counterclockwise toward zero.

I exclaimed in my best airline pilot voice, “Uh … Jack, we didn’t lose the right generator. We lost the right engine.”

A long two seconds passed. Jack scanned the EICAS screen and offered an uncharacteristic expletive that began with an “s.” The next moment was spent tossing our breakfast trays onto an empty jumpseat behind us. I called for the engine-failure checklist and continued to fly the airplane. Well, more precisely, I continued to allow the autopilot to fly the airplane.

Barely 30 seconds into the event, the flight attendant call chime sounded. I snatched the handset off its cradle. One of the flight attendants in the aft end of the airplane announced, “We lost galley power!” Note to self: The flight attendants are the first real indication of an engine failure. Fighting back sarcasm, I explained the reason for her issue. Her response: “Oh.”

We declared an emergency and landed uneventfully at O’Hare, accompanied by the standard series of emergency vehicles with an array of flashing lights. Although it was my leg, having flown from the time of engine failure, I deferred the landing to Jack, hoping he would decline the offer. Nope. The captain took the glory. Admittedly, he did a nice job.

Our arrival at the jet bridge was greeted by a handful of suits and ties, mechanics and a lot of questions. Once the activity subsided, Jack and I marched ourselves to the gate for our next departure as if it was just another day. The diagnosis: The fuel control unit had sensed an erroneous pressure drop and shut down the engine.

Upon reflection, I would have made different decisions. First, when the engine failure occurred, we had just passed Detroit. It was my fault for not being assertive enough to advise the prudent option of diverting rather than continuing to Chicago even though the time difference wasn’t much longer. In addition, Jack never told the passengers about the problem; their only clue was the emergency vehicles chasing us down the runway. Now, after 28 years in the left seat, I find honesty to be the best policy, especially in preparing passengers for an emergency.

My second engine failure at the airline occurred in a 727-200. I was a bright and shiny new captain. Despite my standard briefing to the flight attendants for them to disregard sterile cockpit procedures if anything unusual was observed, they failed to advise me that the number one engine “sounded funny” during taxi.

When I slid all three throttles forward for our takeoff on JFK’s Runway 4L, the airplane didn’t seem to accelerate normally. And the number one engine’s indications were misaligned with the other engine gauges. I aborted the takeoff at 85 knots and taxied back to the gate.

While the passengers deplaned, my flight engineer rode up on a scissor jack platform that the mechanics had positioned behind the number one engine. With a sheepish grin, she enthusiastically reported her findings, suggesting that I see for myself. Turbine blades were bent, twisted or completely missing as if a cannonball had been shot through the engine. In a sense, that’s what occurred. A bearing from within one of the turbine rotor stages had committed suicide.

Although none of these engine events could be considered hair-on-fire, life-threatening circumstances, their outcomes could have been far worse. Because of engine design, reliability and crew training, they became just another day at the office. OK, maybe with just a little added adrenalin.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox