Post-Flight Checks Can Expedite the Preflight Process

A longtime contributor and pilot illustrates why it’s important to make the end of one flight the start of another.

Looking to mitigate a problem? It helps to start the process after your previous flight. [Courtesy: Peter Garrison]

The other day I was reminded, once again, of the trouble with a preflight inspection: When you find something wrong, it’s too late to do anything about it.

I was doing my routine run-up. My homebuilt’s quaint touches include a toggle switch for each mag. When I clicked the left switch to “off,” the rpms dropped by several hundred, and the engine ran rough. Usually I see mag drops of just 50 or 75 rpm, so this was disconcerting. I went through the usual fouled-plug routine of running up to high power, leaning the mixture, and verbally encouraging the offending plug to clean itself out. When I repeated the mag check, however, nothing had changed.

“Whiteman Ground, Two Mike Uniform, returning to parking.”

Assuming it was a fouled plug, I thought about how to identify the culprit without having to pull and inspect all 12 of them. I quickly discovered I was in doubt about a couple of rather-basic questions. When I wired the P-leads—those are the wires that connect the mags to the mag switches—20 or so years ago, did I wire them so that turning off the left switch meant you were testing the left mag or the right? I could imagine either answer making sense. The simplest explanation was that “L” above a switch meant that switch was connected to the left mag. But I could also imagine that the “L” means “this switch tests the left mag.” After all, you’re looking at a label that says “L,” and now you’re supposed to say to yourself, “That means right”? Does that make sense?

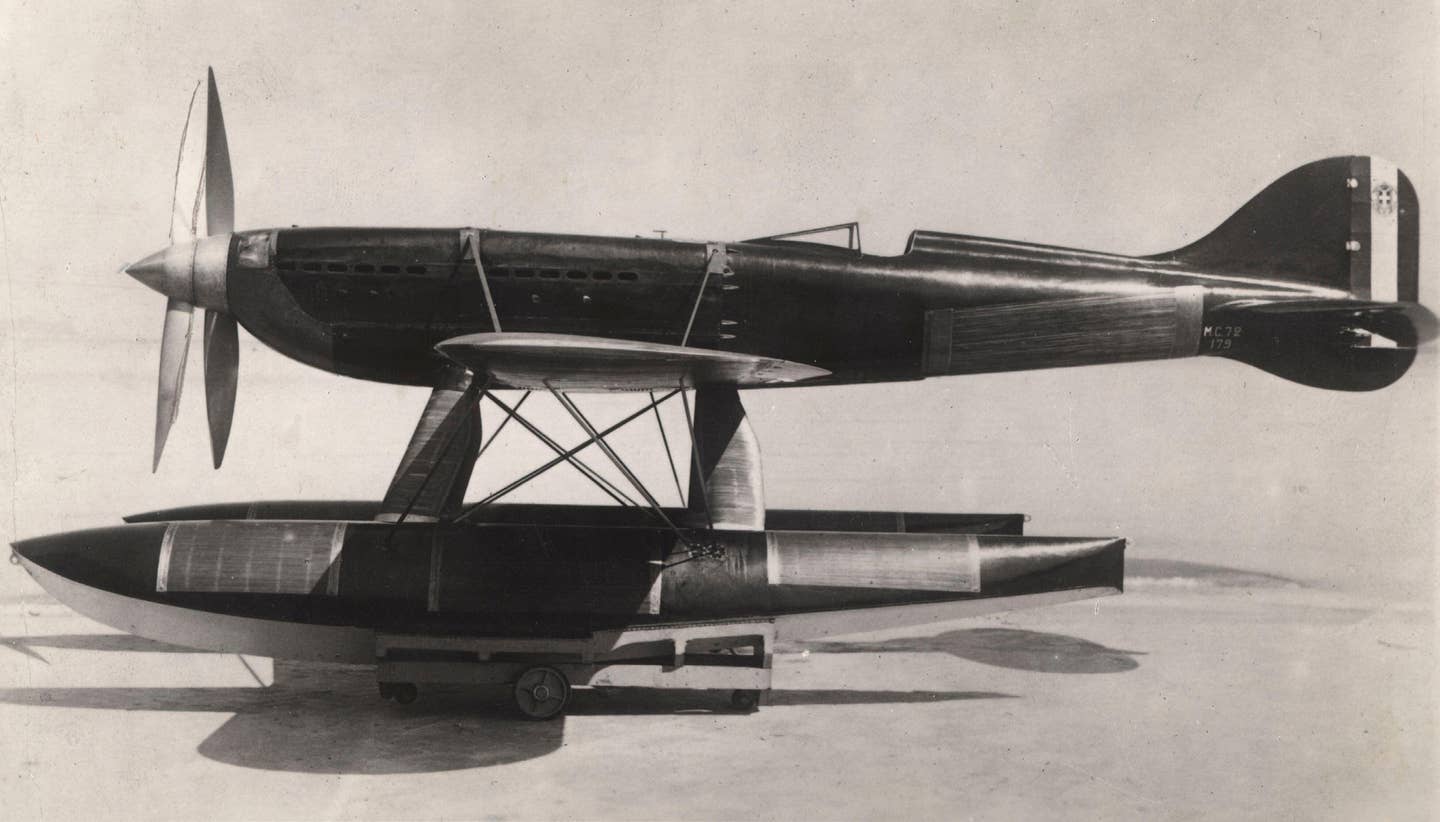

Besides, there was another question: How did the mags relate to the cylinders? The engine manual was at home, so no help from that quarter. This may seem a strange thing for me to be confused about—because I had built the airplane and installed the engine myself—but I guess it had never occurred to me that I might care to know where the plug leads went. Additionally, you can forget a lot in 20 years. The leads converged into thick bundles of blue bucatini—impossible to relate the ones going in to ones coming out. I suspected that each mag drove the top plugs on its own side and the bottom ones on the opposite side, which seemed to make intuitive and aesthetic sense. I went to a nearby maintenance hangar to check. The A&P shrugged. He had seen them wired all sorts of ways, he said, including all left plugs to the left mag and all right ones to the right (an arrangement that virtually guarantees an in-flight emergency and would seem to make a run-up with a 100 rpm mag drop impossible).

So I cut the tie wraps on the clumps of plug leads. Indeed, they were wired as I originally suspected, left mag to top left plugs, etc. I re-bundled them in such a way that if the question ever arose again, I would more easily see the answer. I then checked P-lead continuity with a multimeter and determined that the toggle switch marked “L” was indeed connected to the left mag—as any child would have thought, had a child been available to consult. When I flipped the “L” switch to off, I was testing the right mag.

So, the problem was most likely one of the left bottom plugs; fouling tends to favor bottom plugs. I pulled them. All clean.

I talked with another A&P. He suggested that, if I had EGT probes on all cylinders—I do—I should look at the EGTs while running up. The EGT in a cylinder should rise when one plug is not firing, because the fuel-air mixture in the cylinder takes longer to burn and so the gases going out the exhaust pipe are hotter.

I performed that test, and the result was dramatic. The EGT on the No. 1 cylinder—the right rear cylinder on a Continental—was unusually high to start with, and when I shut off the left mag, the EGT dropped down to the peg. In other words, when the bottom plug on the No. 1 cylinder was turned off, the cylinder went dead.

So the villain was the top plug in No. 1. I replaced it and did another run-up. Now, it was normal. The defective plug, a fine-wire type, looked perfectly all right; whatever the failure was, it was internal. It must have failed during the previous flight, probably toward the end, when reduced power settings would mask a misfire in one cylinder.

But this flight was a scratch. It was just going to be a pleasure flight, so no great loss, but it could as easily have been an important business trip—that is, if I were a person who had important business. But it got me thinking again about this fundamental disadvantage of preflight inspections. If you find something wrong, it’s too late to remedy it.

The Advantage of the Preflight Check

Maybe the preflight checks should have taken place at the end of the previous flight. I should do a run-up at the end of a flight as well as at the start.

I passed this thought by my friend Peter Lert, the polymath, who added that momentarily switching off both mags while idling provides a check of P-lead continuity. In other words, it verifies that you are not parking with a “hot prop.” Apparently, there are some keyed ignitions in which it’s possible to get a drop on each mag separately but still have a hot prop when the key is turned to off.

“Like all unfamiliar practices, this one felt odd, but I will probably get used to it.”

Returning from a trip a couple of days later, I tried out the new routine. Normally, I cut the engine a couple hundred feet before reaching my hangar and let momentum carry the airplane the remaining distance. It’s soothing, the way it coasts silently to a stop. This time, I taxied up to the hangar with the engine still running, performed a run-up and mag check, did the both-mags-at-once check, and only then shut down.

Like all unfamiliar practices, this one felt odd, but I will probably get used to it.

The other thing that can slow you down at the start of a flight is oil. Checking oil at the end of a flight is not so practical; a good deal of oil still coats the internal surfaces of the engine, so the dipstick indication is inaccurate. But still—is it useless? Possibly, because oil drains back into the sump rapidly at first, then more and more slowly, so the relationship between the post-flight dipstick reading and the reading when the engine is cold is variable, depending on how soon after shutting down you look.

Nevertheless, I intend to give it a try. I’ll check the oil after landing and then again before flying. If I find that the post-flight reading has a reasonably consistent relation to the preflight one, I’ll know at the end of a flight if I need to add oil. Not at the beginning, when I’m already running late.

Editor's Note: This article originally appeared in the November 2021 issue of FLYING.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox