Chris Gall

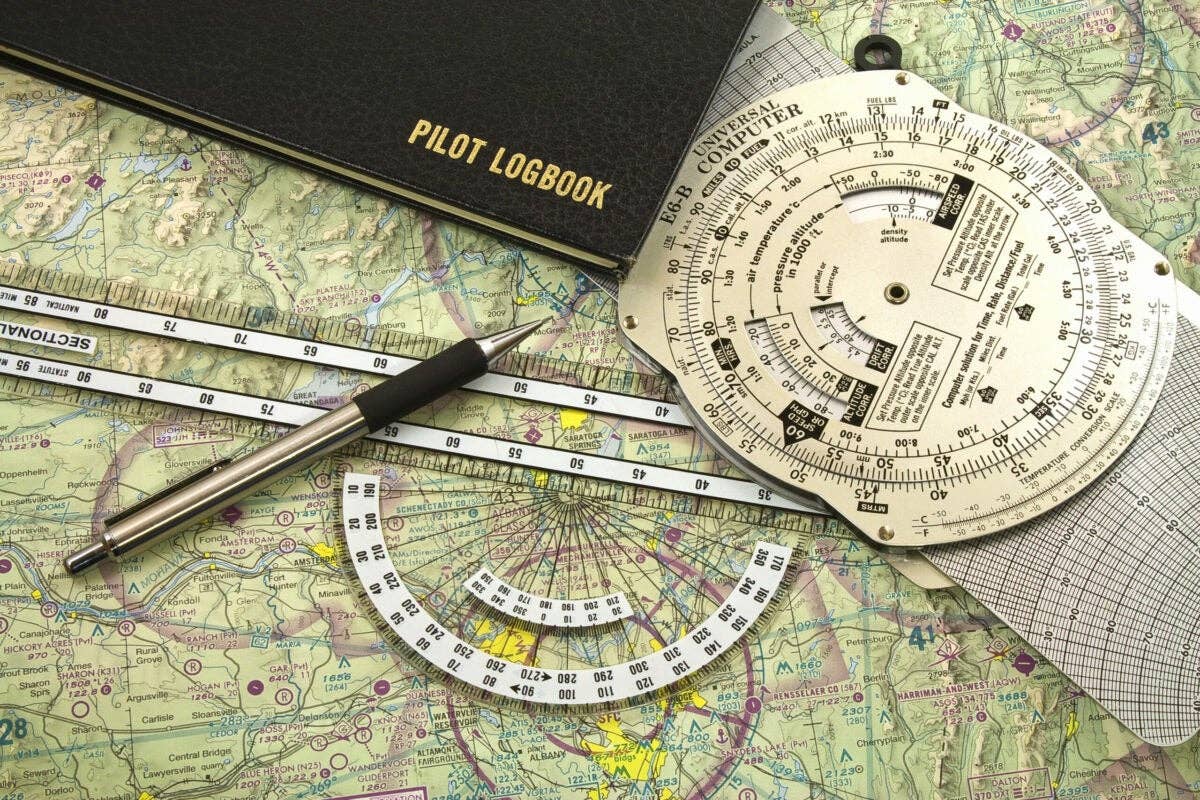

I sometimes chuckle when I think about the complexity of the electrical systems in new airplanes, particularly single-engine airplanes. Most current production singles have multiple electrical buses, more than one electrical power source and, often, emergency backup batteries. And that's great. But there is still only one engine, and if it quits, the airplane is not going to continue flying for long.

The level of sophistication of the electrical system in singles tells you just how important electricity is for safe flight. Pilots who are willing to fly in the clouds with only one engine demand backups and redundancy for the critical avionics and other systems powered by electricity.

Look at a new "glass" cockpit and it's easy to see why we are so dependent on electrical power. Some airplanes still use vacuum pumps to power a backup attitude gyro, but increasingly even the backup instruments are powered by electricity. Maintaining a constant flow of power after some elements of the electrical system fail is the only way a pilot can maintain control of the airplane in clouds or low visibility. In other words, you could glide to a forced landing if all engine power were lost, but without reliable power to fundamental flight instruments, it would be impossible to maintain control without visual reference, and that almost always ends in a fatal crash.

The electrical system wasn't always so important. In decades past, many thousands of light airplanes had no electrical system at all. Pilots propped the engine by hand to start it; a battery powered the navigation lights, if there were any; and mechanical energy powered everything else necessary for flight. In some airplanes, such as the two-seat Cessna 120, the electrical system was an option.

As reliable electrical power became more essential, airplane designers and pilots focused mostly on multiple charging sources. Generators and alternators are among the least reliable components in any electrical system, so it was obvious that they wanted more than one. Most pilots thought the second alternator was as important in a piston twin as the second, but minimal, source of propulsion from the engine was. To many pilots, flying in the clouds or at night with only one generator or alternator was simply foolhardy, so twin sales flourished.

This same line of reasoning led modifiers to devise methods for installing a second backup generator on the only engine in piston singles. These units were typically low in capacity and provided only enough current to power essential equipment such as a communications radio and transponder, but they were better than nothing.

Before long, the manufacturers of singles jumped on the bandwagon and offered second generators or alternators, and these grew in power capability to where most everything on the airplane would continue to operate after failure of the primary alternator. A major selling point of the twin — a second electrical power source — was eliminated.

Multiple power-generating sources are, however, only one of the desirable backups in a truly reliable electrical system. A second or even third generator is the foundation of a reliable electrical system, but there are many other failures that can leave you without power unless there is careful design of the entire system.

Isolation Is the Key All electrical systems have buses to which individual power-using items are connected. A bus is a common wire, often of high capacity, to which several power users are connected. For example, think of the circuit-breaker panel in your house. One breaker may control power to kitchen outlets. That circuit of outlets could have several items plugged in, such as a refrigerator, blender, mixer and so on. That's how a bus works. It is a common source of power for several related electrical loads.

The starting point — literally — of an airplane electrical system is a battery bus, which, as the name implies, is powered by the battery. The starter connects to the battery bus, and once the engine is running and the alternator is on line, the battery is recharged through the battery bus.

In simple electrical systems, all other buses are connected to the battery bus and then distribute power around the airplane. At first thought, that seems like a good idea. The alternator is sending power to the battery bus, and if the alternator fails, you can continue using stored energy from the battery for many minutes. But as in all things electrical, there is a trap in having the battery bus always on line.

For example, what if the big wire connecting the battery to the battery bus chafes through and shorts out to the airframe? Within seconds the alternator will be fried and the battery power will drain uselessly to ground. In reality, all that failed was the wire from the battery, while the alternator was working perfectly until it too was shorted out by that single failure.

The way to prevent this situation is to isolate the battery and its bus from the entire electrical system so that its failure can't take down the whole system. If there were isolation, only the battery and its stored power would be lost while the alternators would continue to power the rest of the system.

Isolating the battery bus is most important because it has such large capacity that is necessary for engine starting. Turbine-engine starters can draw 1,000 amps, or even more, for a brief period when we engage the starter. Even piston engine starters can draw hundreds of amps initially. That means all of the wires connected to the battery and its bus must be huge, and the failure of such large wires could short out the entire system almost instantly without proper isolation.

Every other electrical bus and component in the electrical system can also short out and drain power away from the whole system without proper isolation. A short circuit also typically creates a great deal of heat as more electrical current flows through a wire too small to carry the load. That's another reason every electrically powered item must be protected by a circuit breaker, but the threat to the entire electrical system is a more complicated issue.

Because it is not possible to fully protect every connection from a massive short, or the failure of a circuit breaker, the electrical systems in recently designed transport airplanes, and in some newer light airplanes, are physically separated during flight.

In these most redundant electrical systems, the airplane is usually split in half because there are two engines and two generating sources. The right- and left-side electrical systems operate in parallel with each other, supplying power to individual items, and the operation is transparent to the pilots. For example, the primary flight instruments on the right side of the airplane come from the buses on that side with no connection to the electrical buses on the left side. If a massive failure wipes out the buses on one side of the airplane, the other side continues to function normally.

In these split-bus airplanes, the pilots have the capability to "tie" certain items to the cross-side buses after a failure. For example, if the generator is lost on one side but the buses themselves are OK, power can be sent from the operating generator to the side with the failed generator. The airplane is now in an abnormal situation and some redundancy is lost, but all equipment is still powered by the remaining generator. Circuit breakers protect the "good" side so the pilot is no worse off in terms of redundancy than he would be in an older-design common bus airplane all of the time.

In many airplanes, the bus switching and isolation are automatic after engine start, but in some you move switches to separate the buses. Even some piston singles have separated buses with one, usually a smaller-capacity, bus assigned to power primary instruments and avionics. Total electrical bus isolation is required for engine fadec because, being a computer, the fadec cannot operate without electricity, and if the fadec fails, the engine quits. Remember, the "f" in fadec stands for "full authority," including the authority to shut the engine down.

There is no way for a pilot to change the design and function of the electrical system in his airplane, or to add bus isolation that isn't there. But when shopping for an airplane, you can add an independent electrical system with solid bus isolation to your list of desirable features.

| Alternators or Generators? Electrical power in airplanes is created by either alternators or generators, and on many jets there are both. Alternators and generators convert rotational energy into electrical power, and for the most part, their functional differences are transparent to pilots.The fundamental difference is that generators produce direct current and alternators create alternating current. In general, an alternator creates more power for its size and weight than does a generator and can also produce more power at lower rpm. That's why alternators are the norm on piston engines.Generators are the norm on turbine airplanes, at least until you get to the larger jets, because a generator can also function as a motor and, thus, as a starter-generator. Power is applied to the starter-generator to spin the turbine for starting. Once the engine is up and running, the process is reversed and the unit creates electrical power, as much as 400 amps in some airplanes.Most equipment in an airplane is designed to operate on direct current, so the power from an alternator is "rectified" into DC. Diodes, which are sort of an electrical one-way valve, do the rectifying on the typical airplane alternator. Most alternators have several diodes and can continue to produce usable power after the failure of one or two. Sometimes you can hear a new or increased humming or static noise in your headset when a diode or two has failed but the alternator is still producing some power.The frequency of the alternating current from an alternator is relative to its rpm. In older-design airplanes, turbines in particular, a constant 400 hertz AC is most commonly used to operate some avionics, gyros and flight instruments. But other functions, such as heating elements in windshields, don't care about AC frequency, so they use "wild frequency" AC, which means the frequency varies as enginespeed changes the rpm of the alternator. |

It's easy to become confused by the bus architecture of an airplane, particularly turbine airplanes, and believe that more, in terms of buses, is better. But that's not necessarily true. Jets that trace their design roots back to the 1960s and '70s have scads of buses with obscure names that lead to a maze of circuit breakers spread around the cockpits. A modern system has few buses, and even fewer circuit breakers, but the isolation of the critical items is complete, and operation of the system is automated. What typically determines the sophistication of the electrical system is when the airplane was designed and certified, not when it was built, because the FAA does not require manufacturers to meet the current certification standards until they change the design of an airplane in some substantial way.

Circuit Breakers

Every pilot knows that a circuit breaker is designed to pop to prevent too much power from flowing into and overheating a shorted circuit. But in many airplanes, a CB also functions as an on-off switch. In abnormal situations, it is often standard procedure to pull a breaker even when there is no evidence of a short circuit. For example, in virtually all procedures for emergency landing gear extension, the pilot pulls the gear-operating breaker so that errant and unwanted signals can't be sent to the gear during or after emergency extension.

For decades, the FAA demanded that pilots be able to reach and pull, or reset, circuit breakers for almost every item connected to the electrical system. The thinking was that it was about as important to be able to depower a system by pulling a breaker as it was to be able to restore power by resetting a popped breaker.

That certification theory has changed, and in recently designed airplanes, circuit breakers are moving out of the cockpit and out of reach of pilots. The new thinking is that pilots can screw things up by resetting a breaker that shouldn't be touched more frequently than they can return everything to normal by resetting a CB that popped for no valid reason.

The "old" CB management technique that almost all pilots were taught was to reset a breaker once after it popped, but if it popped again, to leave it alone. Most circuit breakers are thermal — a few are magnetic — with a conducting element designed to carry a specific electrical load. If too much current flows through the breaker, the conductor heats up and expands, which is what pops the breaker. The process is quick, and it is possible that a temporary and nonthreatening transitory load could cause the breaker to pop and resetting it would not be hazardous. But that's rare. A properly functioning breaker doesn't pop unless the current draw on the circuit it protects is too high, and the reason for the opening of the CB should be investigated.

The National Transportation Safety Board is so concerned about resetting breakers that it wants the FAA to examine the validity of the instruction to check all circuit breakers, and that is at the top of almost every prestart checklist. The NTSB believes that resetting the CB on a weather radar led to an inflight fire and crash because the pilots flying the airplane that day didn't know that the radar had failed for other pilots on an earlier flight and the breaker had popped.

The point is that no popped breaker should be treated casually. However, we need to use common sense. For example, many maintenance shops will pull breakers on the landing gear so that the gear can't be accidentally operated, which could injure people working on the airplane or drop the airplane on its nose. So if you pick up your airplane at the shop and see the landing gear CB out, it would make sense to reset it. But if nobody has been in your airplane since the last flight and you find a popped breaker, it would be wise to investigate the cause because it could have been an unnoticed problem that happened on the last flight.

Another reason to move CBs out of the cockpit is that moving them reduces the number of, and size of, wires that need to be routed through a crowded space. With remote CBs, the wires can run from the battery and alternators more directly to the equipment they power without a detour into the cockpit to be run through a CB. Modern crew advisory systems (CAS) can tell the pilots that a remote breaker has opened, so they remain informed without seeing the breaker. And, in current design transport airplanes, there is always a backup so that the function powered by the popped breaker is not lost.

You may also find current limiters in some complex electrical systems. These are fuses with a "slow" burn so they can carry an overload current for a brief period. Current limiters are typically used to link buses with high potential loads, often hundreds of amps. With so much power possibly flowing between buses, a transitory overload is possible, and the current limiter can carry it without endangering the system. However, once a current limiter burns through and fails, it cannot be reset and must be replaced when the airplane is on the ground.

One unexpected use of CBs that I have found with some integrated avionics systems is to "reboot" an individual element of the system. Sometimes, just as with your other computers, powering down and back up will restore the function of some part of the system that is connected to a common on-off switch. The CB can reboot individual functions without killing the whole system.

The bottom line on CBs is to forget what we had been taught and not reset them even once without considering why they are out in the first place.

The Avionics Master

Most airplanes have a dedicated avionics bus that is connected to one of the primary buses with a relay. The avionics master allows the pilot to depower all avionics with a single switch instead of turning off each individual item.

Earlier avionics were sensitive to voltage spikes and could be easily damaged by even a very brief surge, which can take place, for example, during the engine start sequence, so it was standard procedure to leave the avionics master off until all engines were started and the generators were on line.

Most airplanes still have an avionics master, but its function has become less important because recently designed avionics have power supplies that can handle a wide range of voltage. Most avionics will function with voltage between 9 and 33 and can withstand even higher spikes without damage, so starting the engine with the avionics powered up is not the issue it used to be. The most fundamental avionics in a glass cockpit. such as the primary display and electronic gyros, are functioning as soon as any power is applied, so you can see how well modern electronics can withstand power surges.

In many airplanes the avionics master relay is powered closed, meaning to turn off avionics power you would need electrical power to the relay. When you turn on the master switch, the avionics relay is closed, and for an instant power flows to the avionics until the relay can open. When you turn on the avionics master switch, you take power away from the relay and it closes, allowing power to flow into the avionics bus. The important issue here is that there is also an avionics master CB in this type of system. If you lose power to the avionics bus, you can pull the breaker, and that might solve the problem by removing power from the relay. It sounds backward to pull a CB to restore power, but that's how this type of system functions.

Master Switch vs. Battery Switch

Many light airplanes have a "master" electrical switch, while more complex airplanes have switches for the battery and then for each generating source. The functions are similar, but there are very important differences.

The master switch, as the name implies, connects the entire electrical system to the battery bus. It also engages the alternator that is connected to the battery bus.

A battery switch does exactly what its name suggests and connects the battery bus to the system. However, each generator or alternator has its own on-off switch so it can be controlled independent of the battery. This is important because you could have a battery or battery bus failure and you would want to isolate that from the entire system without losing the generating source. In this type of electrical system, everything operates normally with the battery turned off once the generators are on line.

It is common practice for pilots to disconnect the battery in business jets so that some forgotten light or other load that is connected to the always-on "hot" battery bus won't drain the battery as the airplane sits. It has happened that pilots forgot to reconnect the battery, had a ground power unit hooked up to the airplane for engine start, turned on the generators and took off with no battery power available. Legend has it that some pilots have even departed under the same scenario without a battery even installed in the airplane.

| Why 14 or 28 volts? Many pilots mistakenly believe their airplanes have 12- or 24-volt electrical systems because that is the voltage the battery provides. But the systems are designed to operate normally at 14 or 28 volts. The reason for the difference between the battery and the normal operating-system voltage is that the battery won't charge properly without the extra couple of volts. If the electrical system were regulated to 12 or 24 volts, the battery would not recharge during flight. A 28-volt system is generally more efficient than a 14-volt system because the same amount of electrical power can be carried in smaller wires. Remember, usable electrical power is the combination of volts and amps. The same number of amps has approximately twice the useful power at 28 volts, but the motors, lights, avionics and other electrical equipment can be the same size and weight, or even smaller, than if operating at 14 volts. Historically piston singles had 14-volt systems and most multiengine airplanes operated at 28 volts. By the mid 1970s, manufacturers began to upgrade the singles to 28 volts to take advantage of the greater efficiency, and virtually all recently produced airplanes have 28-volt systems. When the change was first made, many pilots groused that they couldn't jump-start their new 28-volt airplanes from their 12-volt car batteries, but everyone seems to have gotten over that one little tradeoff to enjoy the much greater power available in the 28-volt system. |

The real threat in having no battery power available is that it is the ultimate backup source of power. There must be enough battery power available to power the critical items for IFR flight for 30 minutes in recently certified airplanes. What items are on that emergency list are different from airplane to airplane, but primary instruments, com radio, transponder and basic cockpit lighting are always available.

The battery also serves as a sort of shock absorber for the electrical system, relieving the generators during the momentary high drain of some systems. For example, the electric motors that power the landing gear in many airplanes can draw more current than the generators produce at the start of an extension or retraction cycle, and the battery supplies those extra amps. If the battery weren't there, bus voltage could fall so low that avionics would drop off line.

Some standard procedures call for starting the engine or engines with the alternators off under the theory that the alternators are adding at least a tiny amount of resistance to engine rotation during the start sequence. I can't imagine that it matters, so I leave the alternators on in my Baron during engine start, but either way works fine as long as you remember to turn them on as soon as the engines are running.

Know the Buses

The design of the electrical system is out of every pilot's hand, but it is absolutely necessary for each of us to understand how it operates and where the threats to continued function are, and to have the knowledge to isolate failed circuits or buses and restore power when possible.

In complex airplanes such as jets, many hours, and even days, are spent in the classroom and simulator learning every detail of the system so pilots can recognize failures when they occur, and prevent the failure from spreading or restore power safely to circuits that are not damaged. As in all other aspects of flying, automation has made electrical system management less critical for pilots. For example, in most newer airplanes, high draw items will be "shed" automatically if a generator is lost. But thorough knowledge of the entire system is still the only way to get through the cascade of failures that will be thrown at you in the simulator, and possibly in real life.

Even with the most basic electrical system, the pilot needs to understand how it functions and where the critical failure items are located. For example, if the starter relay sticks and the starter remains energized after start, all of the power the alternator can produce along with battery power will flow into the starter. After several minutes — usually enough time to get into the air — the starter will fry and short out the entire electrical system, leaving the pilot totally in the dark. The way to recognize a stuck starter relay is to check for an abnormally high charge rate after start. So even for the most basic electrical system, there are important ways to prevent small problems from becoming crucial threats.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox