I have written that it is madness to certify light airplanes for flight in icing conditions. Some have misinterpreted that to mean that I don't think light airplanes should be equipped with ice-protection gear. Nothing could be further from the truth. I think the ice protection systems that are available today, and that are not approved for flight in icing conditions, are a great value both for the money and for the utility that they offer.

The reason that I think it is foolish to certify the systems is that certification adds to the cost and complexity without a corresponding increase in usefulness. It might also carry with it some false promise. Certification might suggest to some that the airplane is okay to fly in continuous icing conditions. No problem with flying along cracking the ice with boots or letting TKS fluid ooze out onto the surfaces. That is simply not the case.

The Cessna Caravan is fully certified for flight in icing conditions. It comes from the factory with a boot system. And, as we will see in a minute, it has a checkered history when it comes to successful flight in icing conditions. While the Caravan is not technically a light airplane it bears enough similarities in configuration and performance to be considered alongside piston singles.

First, a look at how we got to the current situation on ice protection.

Light airplanes were equipped with ice protection that wasn't approved for years. Piper Apaches, Aztecs and Twin Comanches all were offered with boot systems. A great fleet of Barons was built with unapproved boot systems as were many twin Cessnas.

The first "modern" single-engine piston airplane equipped with boots was the Cessna 210. Soon after they started putting boots on it and on the 337, Cessna decided to go for approval for flight in icing conditions. The T210 and P210 were the first single-engine piston airplanes to get that approval, in 1979. The Piper Mirage has an approved boot system as well.

As the Cessnas were approved then, they would never pass muster now. They were approved with a single power source (a quite unreliable vacuum pump) for the boots where any airplane gaining approval today will have a redundant power source, which the 210 did in later years.

Cessna did a lot of flight testing on both the unapproved and the approved systems and this yielded information that has been discussed before but is always worth a review. The value is as much for pilots who fly without ice protection as with because it outlines the performance losses with ice accumulation.

Cessna found that the often cited weight of ice isn't really a problem. According to a paper given by Cessna engineer Paul E. Leckman, the weight of an inch of ice comes to 65 pounds and the effect on performance "is negligible when compared with the aerodynamic effects of ice."

Because there was no mention of ice in Part 23, under which light airplanes are certified, the Part 25 (transport category) ice definitions were used in this study. With one inch of ice, a turbocharged 210's rate of climb dropped from over 900 feet per minute with no ice to under 100 feet per minute with FAR 25 continuous maximum icing. With deice boots and prop anti-ice (heat), the rate of climb dropped to just under 700 feet per minute in those same conditions.

From testing, Cessna came up with the following in the P210 pilot's operating handbook:

"An accumulation of ½ inch of ice on the leading edges can cause a large (up to 500 fpm) loss in rate of climb, a cruise speed reduction of up to 30 kias, as well as a significant buffet and stall speed increase (up to 15 knots). Even after cycling the deicing boots, the ice accumulation remaining on the unprotected areas of the airplane can cause large performance losses. With residual ice from the initial ½ inch accumulation, losses up to 300 fpm in climb, 15 kias in cruise, and a stall speed increase of seven knots can result. With one inch of residual accumulation, these losses can double."

All that defines ice as something to stay away from, or get out of quickly, even if you are flying an airplane with an approved ice-protection system. I would add that a lot of Cessna's information came from working with the original unapproved system but it is still valid. The system that was later approved differed only in including a boot on the vertical tail, slightly larger boots on the wing, and a different and totally unserviceable windshield heat system. I can say from experience that there is a definite performance deterioration in ice with the approved system.

Now we have evolved away from boot systems for most new light airplanes as well as from new boot installations on existing light airplanes. BFGoodrich made virtually all of the manufacturer-installed boot systems for propeller airplanes. It still vigorously supports the boot systems that are out there, and replaces systems when they wear out. The current other available and proven ice-protection system is from TKS, through Aerospace Systems and Technologies, Inc. weepingwings.com.

As the website name implies, this is a weeping wing system where a deicing fluid is dispersed through a porous leading edge system as well as onto the prop and windshield. The TKS system is available as both approved and unapproved systems. The Mooneys are currently the only new airplanes offering an approved for flight in icing TKS system. The Cirrus and Piper PA-32 series airplanes are available with a system that is not approved for flight in icing conditions. A number of owners are installing TKS systems on new Skylanes and 206s. Columbia will soon offer a non-approved electric thermal ice-protection system called E-Vade. Boots or TKS, airplanes equipped with either and that are not approved for flight in icing conditions have gone through various levels of testing and the systems are as viable as those that are approved. The main differences would be in redundancy of power sources and, sometimes in the case of TKS, the amount of fluid that is carried.

The boot system is lighter in weight and cheaper than the TKS system but, for now, only the TKS is available on new piston singles (except for the Mirage and Columbia) and as retrofit for a number of popular single-engine models. Boots do have to be replaced occasionally (mine are 20 years old and still okay) and replacement costs almost as much as a new system. The boot system also, according to my POH, costs two to three knots of cruising speed and 30 feet per minute in rate of climb. There should be no performance penalty with a TKS system. The boot system and the TKS system without fluid weigh about the same. The weight of the TKS fluid would have to be subtracted from payload to the tune of maybe 60 pounds for a full load of fluid.

The lowest price shown for a retrofit TKS system is $23,000 for a Skylane. That system is not approved for flight in icing conditions. The price of an approved TKS system on a 210 is $35,000. Jim Dunn, BFGoodrich's boot king, told me that replacement of my boots would run about $13,000. That does not include the plumbing and valves for the system, the heated prop elements or the windshield, but the initial cost of a boot system should still be less than an approved TKS.

The TKS does have other advantages, though. Because it is emitting deice fluid there would probably be less ice accumulation on areas not directly addressed by the system. An equipped airplane should thus have less of a problem with residual ice on unprotected parts of the airplane than would an airplane with boots.

How about the legality of flying with a system that is not approved for flight in icing conditions? The answer is painfully simple. If you do not bend anything or cause a scene in the air traffic control system you can operate as you please. Get in ice trouble with an unapproved system and you'll probably be in certificate trouble. However, were you to survive an encounter with severe icing in an airplane with an approved system the FAA would always have their "careless and reckless" FAR to sic on your certificate.

So, staying out of trouble means making every effort to avoid ice and, if it is encountered, making every effort to get out of it. That's not hard to do because almost every airplane that flies into ice comes from ice-free air that remains available for a return visit.

Now to the Caravan. Even though the airplane is certified for flight in icing, six of 28 fatal accidents in the 48 states have had airframe ice listed as the cause or a causal factor. That is an extremely high number. It does have to be considered that Caravans run on schedules and complete a high percentage of their flights on schedule. In other words, they take whatever Mother Nature dishes out, and, when it comes to ice, they don't always win the battle.

If there is a typical accident related to ice it comes on approach, where an ice laden airplane is stalled. However one Caravan departed from controlled flight in cruise at 9,000 feet, where the calculated groundspeed started out at 158 knots and in eight minutes decreased to a calculated airspeed of 102 knots after which control of the airplane was lost. This was in relatively flat country. Ice can be worse over mountains.

A Cirrus with unapproved ice protection departed from controlled flight at 16,700 feet, over the western mountains. The pilot told controllers he was in icing conditions and was not able to maintain altitude.

That accident may not have had much to do with ice, though. The airplane was over the mountains in an active weather system and there could have been substantial downdraft activity. There are a lot of pilots out there who don't understand the relationship between mountains and wind. Some think it is always turbulent when there are up and downdrafts. Nothing could be further from the truth. You can be in a smooth and strong downdraft and, especially in the case of an airplane operating close to its service ceiling, as was this Cirrus. It would only take a weak downdraft to render the airplane incapable of maintaining altitude.

I think it is much more likely that this Cirrus couldn't maintain altitude because of a downdraft than because of icing that overwhelmed the TKS system on the airplane.

So, ice protection is a great thing to have for use when fleeing ice. It is not worth much for flight in continuous icing conditions. That brings us to many rules of thumb on dealing with ice.

Performance is key in dealing with ice. Jets don't have many problems here because of a heat rise in the airframe with higher indicated airspeeds. They also climb like bandits so they get above ice more quickly. Conversely, the slower the airplane and the less the rate of climb, the less you have to give away in icing. Boots crack the ice and the wind blows it away. The faster you are going the better. Most piston twins have more reserve performance (when both engines are running), so they do better in ice than singles.

If flying toward a weather system, a front or a low, any ice that is encountered will likely get worse until you pass by the weather system. Likewise, if you are flying on top and toward a system, the tops will likely get higher.

Speaking of getting on top, icing will likely get worse the closer you get to the tops. That's another strong vote for good climb capability.

Other than performance, wings have a lot to do with how an airplane reacts to ice. An efficient airfoil as used on a Mooney, for example, will show more performance deterioration more quickly than will a Cessna or Bonanza wing, for example. Comanches are more affected than Apaches and Aztecs.

An airplane's reaction to ice might not be linear. Past a certain point, depending on the airfoil, things might go from not so bad to terrible in a hurry.

Getting out of the ice is one thing. Safely landing an iced airplane is another and many icing accidents happen as the airplane is maneuvered for landing. It is best to fly fast and on most airplanes it is best to use minimum or no flaps because elevator effectiveness might be lost when the flaps are deployed. The POH should have word on this. Also make gentle turns if turns are required. All this means that a long runway is best, but a trip off the end of a shorter runway would usually have a better ending than a low altitude stall.

Besides fronts and lows, mountains can be ice makers. Even the relatively low mountains of Pennsylvania can create an aerial icebox. Back in the DC-3 days, pilots would sometimes climb westbound out of Pittsburgh to get some altitude before heading east toward New York or Washington. Mountains carry the double whammy of creating ice and higher minimum en route altitudes.

The Great Lakes can be pretty good ice makers. This comes in lake effect clouds downwind of the lakes when the lakes are warmer than the air and the wind is strong. Lake effect clouds usually top out in the 18,000-foot range so you can't get over them well without a turbocharger. The tops fall dramatically when you get on the upwind side of the lakes.

If flying in clouds, and ice, and the air becomes turbulent, chances are the ice will get worse.

It is often said that ice won't form at outside air temperatures lower than -15° C. It can and does where there is strong lifting.

If you are counting on a surface temperature to be a salvation, it needs to be at least 36° or more to yield a couple of thousand feet of warmer air to get rid of the ice.

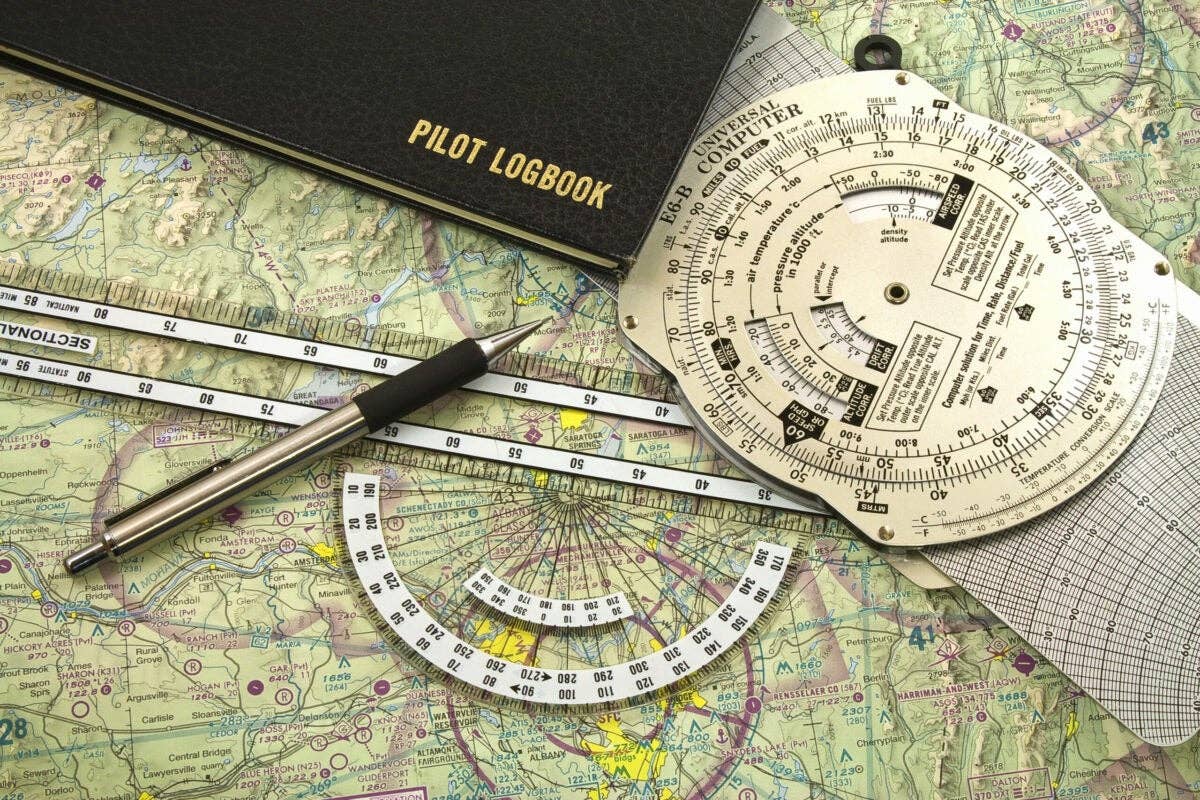

General ice forecasts, as found in Airmet Zulu, are scary and usually cover most of the country that is affected by cold clouds. The best ice forecast is on the ADDS website, adds.aviationweather.noaa.gov/, where it is specifically forecast by area, altitude, and percentage chance of icing.

To be useful, pilot reports on icing have to be pretty new, be specific to the area in which you are about to fly, and be from an airplane in the speed range as the one that you are flying.

I like to say that my primary use of ice protection is while I am going for help, in the form of warmer or ice-free air.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox