Snow comes to New York-area airports like a regularly scheduled operation—and it’s hard to opt out for pilots. Taiga/Shutterstock

A certain amount of an airline pilot’s life is given over to marking time on and around airports, and that is doubly true of the junior captain on reserve. I am currently ensconced in the midcentury-modern environs of the TWA Hotel, built around Eero Saarinen’s soaring TWA Flight Center at John F. Kennedy International Airport. I’ve been here going on 36 hours, thanks to a stint of short-call reserve yesterday followed by an assigned trip later today. In the meantime, New York’s first big nor’easter of the season blew in last night and is burying the city under nearly a foot of wet snow.

So I’m leisurely drinking my morning coffee in the flight center’s sunken lounge, watching big fat snowflakes swirling past the curved glass edifice and piling atop the sleek form of the Lockheed L-1649A Constellation parked outside. I check my flight’s status—already more than an hour late. More worrisome: If the snow doesn’t end soon, I’ll have to deice. I haven’t done so in nearly five years, an impressive streak I’d prefer to continue.

Any professional pilot reading that last sentence undoubtedly just raised a critical eyebrow. “Aha!” you say, “I knew Sam was a wild man. His piratical, rum-soaked sailorly ways have clearly corrupted his professional mores. Here is one of the few surviving cowboys, the captain who blithely takes off with frosty wings even as wide-eyed passengers film the transgression and post it to Facebook.” No, no, that’s not it; I’m just as conservative about deicing as the average airline pilot these days, which is to say quite cautious indeed.

My streak is mostly a product of not having flown much during the three winters Dawn and I were out cruising the Bahamas and Caribbean aboard Windbird. I was based in Atlanta then, and when I did fly, I purposely bid winter layovers in the southern US, Caribbean and South America. This pleasant interlude was bookended by two winters largely spent in training or sidelined by the pandemic. There was undoubtedly a good string of luck, times that the sun melted the last bit of morning frost just before pushback. So, the last time I deiced was on February 2, 2016, in a Boeing 767 during a Minneapolis snowstorm.

During my first decade of Part 121 flying at Horizon Air and the now-defunct Compass Airlines, I was based exclusively in northern cities and seldom bothered to bid away from snowy climes. Though Horizon’s hubs at Portland (KPDX), Oregon, and Seattle (KSEA) are fairly temperate, many of their destinations across the Intermountain West experience the full gamut of winter weather. At the small Montana stations, you’d see the same few agents checking in passengers, loading bags, pushing back the airplane and then jumping in the deice truck. They did a fantastic job in often difficult conditions.

At Compass, I was based in Minneapolis, where the art and science of deicing airplanes en masse has been honed to perfection. I again flew to Montana quite a lot, as well as destinations across the snowy Upper Midwest and, for the first time, the Northeast—where truly execrable weather is compounded by jampacked airports and airspace to create operational catastrophes that reverberate across the system days after the storm has moved on. No wonder I’ve been hiding from Old Man Winter during the past five years.

As a captain, the FAA charges me with ensuring that the aircraft is entirely free of ice, snow and frost before every takeoff (with a few narrowly delineated exceptions). Airframe contamination can be surprisingly pernicious, considering that the preflight is done from ground level and contaminants mostly adhere to upper surfaces. Additional inspections from the jet bridge and cabin are necessary. Even when icing conditions don’t currently exist, you have to be careful there isn’t leftover contamination from the night before, and variable conditions often require an additional check before pushback.

Once the need for deicing has been established, procedures vary by airport. At small stations, deicing is usually done at the gate or just after pushback. At larger airports, it is more common to deice with engines running at a remote deice pad, and the major hubs often have multiple pads of several lanes each with two to three trucks per lane. My current airline has good deicing manuals and checklists for various situations, making deicing a fairly simple affair. Still, the autumnal installment of our quarterly online ground school invariably includes a refresher on deice procedures to get us back up to speed for the coming winter.

There are two types of deice/anti-ice fluid commonly used in the US. Type I deice fluid is a thin orange glycol that is applied hot and at high pressure. It is excellent for blasting the airframe free of contaminants but provides very limited future protection owing to its low viscosity. It is sometimes used alone when active icing conditions no longer exist, or when conditions are very light and no delay is expected before takeoff. Otherwise, a two-step process is used, and the Type I application is followed by Type IV. This viscous, green-colored anti-ice fluid is applied cold, and is designed to soak up contaminants and then shear off the airframe during the takeoff roll. Once fully saturated, however, it no longer can be guaranteed to shear evenly and is said to be “failed.”

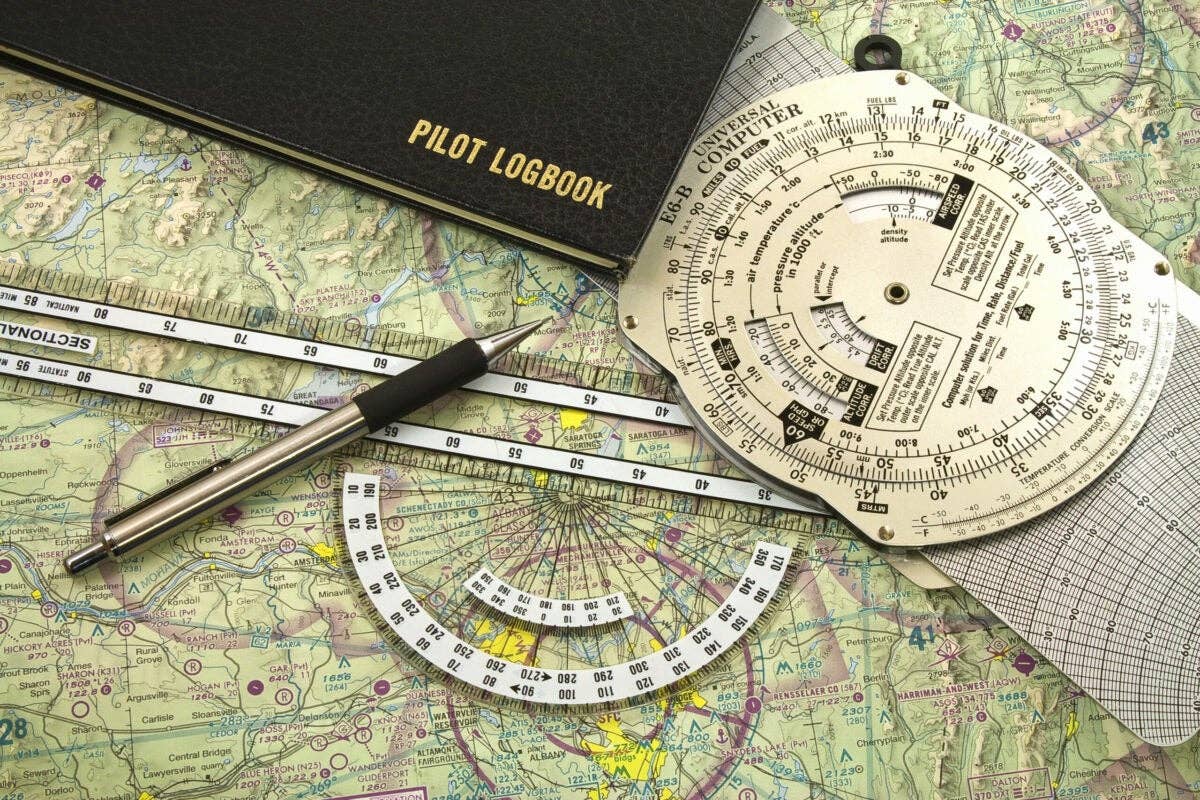

For this reason, the crew must determine maximum elapsed time between fluid application and takeoff (via tables in the deice manual or, as at my airline, an iPad app). Holdover time varies by fluid type, brand and dilution, outside air temperature, and type and intensity of precipitation. Even then, this is not an exact science: Holdover time is given as an approximate range. For example, generic Type IV fluid applied at 100 percent concentration with an outside air temperature of minus 5 degrees

Celsius in moderate snowfall has a holdover time range of 23 to 42 minutes. It is up to the captain to “apply English” to determine what time to use. Is it “light” moderate snowfall or “heavy” moderate snowfall?

Read More from Sam Weigel: Taking Wing

Let’s say that I look outside and decide that the snowfall is on the lighter end of moderate; I write down 42 minutes and hack my clock as Type IV application begins. Once deicing/anti-icing is complete, we complete our post-deicing checklist, exit the pad, and join the queue for takeoff. Our dispatcher sends us an updated field-condition report, which shows Runway 30L to be 75 percent covered with a half an inch of wet snow, and runway-condition codes of 3/3/2, prompting us to request updated contaminated-runway performance figures. The new numbers yield a 10-degree-flap takeoff with slower V-speeds. The first officer sets the flaps to 10 and reads the performance-change items from the preflight and taxi checklists.

Tower reports the wind as 260 degrees at 19 knots, gusting to 28; without prompting, the FO pulls up the appropriate tables on her iPad and determines that the crosswind component is nearly 20 knots, the maximum recommended crosswind with medium to medium-poor braking action. We reach a fairly clear section of taxiway, and I stop, hold the brakes, and run the engines up to 70 percent N1 for 30 seconds—a required procedure to clear any fan ice. Another Boeing 737 just ahead of us does the same, shaking us with jet blast, and I realize that this requires a reduction in holdover time. OK, let’s call it 30 minutes.

But now takeoffs have paused for several arrivals, and it’s clear that we won’t quite make it in time. All is not lost; even with holdover time expired, we are allowed to depart with a cabin check within the previous 5 minutes. When we are No. 2 in line for takeoff, we coordinate with the tower and flight attendants, and I exit the flight deck and stroll back to row 20 to peer at each wing, putting on a nonchalant air for the passengers. The green anti-ice fluid is still quite glossy, which is good. If it were dull, this would indicate fluid failure and a need to repeat deicing/anti-icing. If I wasn’t sure, I could request an external check from one of the deicing trucks. There’s a lot of judgment in all this, built by experience and tempered by the knowledge that several airliners have crashed after inadequate deicing. This is the sort of day that justifies every penny of my hourly rate and then some.

For all the minute attention paid to deicing at the airlines, it’s quite rare in GA; I’ve never deiced a light aircraft in 27 years of flying them. Small airplanes are often kept in hangars overnight in colder climes, taxi times are negligible at most GA airports, and we don’t usually fly during heavy snowfall because of the threat of in-flight icing. I did fly light twins with deice boots while freight-dogging for a couple of Part 135 operators. Their ground-deicing programs, however, involved a stiff brush and maybe an ice scraper. I suspect my standards of “clean wing” were probably not as stringent in those days. I certainly wasn’t too worried about the bank bags taking incriminating photos on their (then-nonexistent) smartphones and posting them to (then-nonexistent) social media sites. Ah, simpler times.

Enough thoughts about winter weather; I’ll have to operate in it soon enough. The morning stretches into afternoon. I pack my bags, don my uniform, and emerge from the TWA Hotel to trudge over to Terminal 4 through snow and slush. As I do, though, the falling snowflakes slow and then stop as blue sky peeks out through the low sweeping scud. My flight ends up being several hours late thanks to an embarrassing cascade of failures that are all too typical of New York airports on bad-weather days, culminating in a four-minute comedy of errors as an undersize tug without snow chains attempts to push back our lightly loaded 737 across an unplowed, bone-jarringly rutted and terrifically icy ramp. It’s OK, though. I know my job will get drastically easier the moment I push the throttles forward and we hurtle down Runway 4L. And anyways, the airplane is clean of contaminants and no further snow has fallen. My five-year respite from deicing most certainly won’t survive my first New York winter as a junior captain—but for now, the streak abides.

This story appeared in the March 2021 issue of Flying Magazine

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox