Aircraft Building Has Come Out of the Woods

Timber holds a special place as the primordial material in airplane construction.

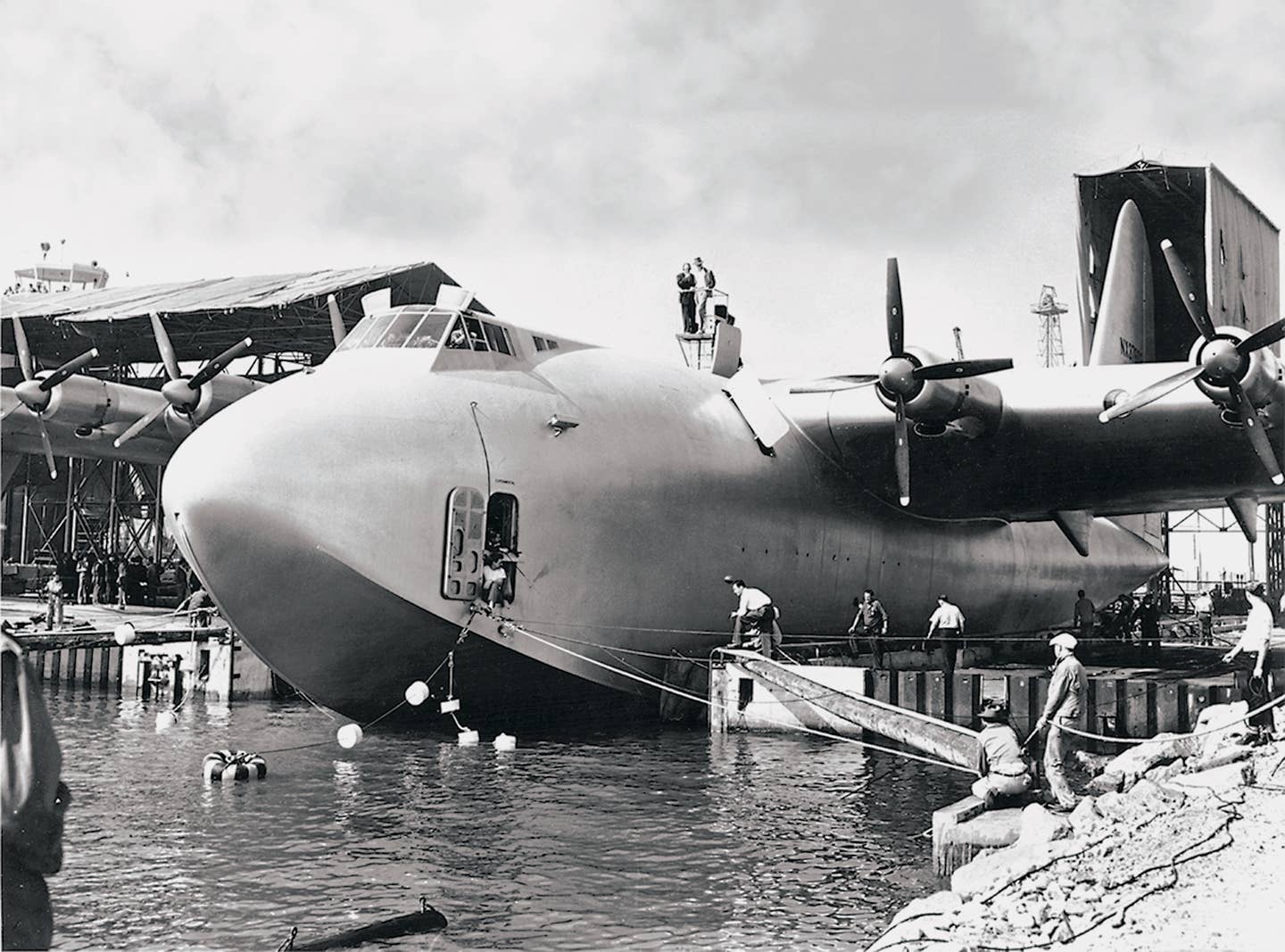

American aviator Howard Hughes (in hat) atop his flying boat the Spruce Goose (a Hughes H-4 Hercules), directing operations for the launch at Long Beach, California, on November 6, 1947. Here the aircraft is towed away from its dry dock on Terminal Island. [Library of Congress]

Among the volumes crumbling on my bookshelves is one entitled American Combat Planes, by the late historian Ray Wagner. Originally published in 1960, it presents trading card-sized photos of countless airplanes, together with their specifications and a running narrative of the history of American military aviation, beginning with World War I. From time to time, when leafing through it in search of something else, I have happened upon a sweet-looking little airplane incongruously wedged between the school bus-sized Republic XP-72 and General Motors XP-75.

If you're not already a subscriber, what are you waiting for? Subscribe today to get the issue as soon as it is released in either Print or Digital formats.

Subscribe NowIt is the Bell XP-77. With a 100-square-foot wing of 27.5-foot span, it resembles a homebuilt, but one whose somewhat massive snout conceals an inverted Ranger V-12 engine of 520 hp. Two prototypes were built. Conceived to be fast, agile, and cheap, it managed only two out of three, topping out at a sluggish (for a fighter) 330 mph. According to Wagner, this was a disappointment because it was supposed to make 350, but it was actually remarkable the prototypes managed to go as fast as they did, considering they lacked superchargers. The project ended ignominiously. One prototype was destroyed when the pilot bailed out of an inverted spin. A second became a “gate guard” at some random Air Force base and eventually deteriorated into firewood.

Yes, firewood—because, as an offspring of one of the U.S. armed services’ occasional brief flings with nonstrategic materials, the XP-77 was built out of wood. I revisited it recently after happening to read an essay about wooden aircraft in World War II. The author, professor Eric Schatzberg, contends wood construction was viewed differently, and succeeded or failed, in different countries—he focuses specifically on Britain, Canada, and the United States—because of unconscious cultural biases that colored the way people perceived successes, failures, and the qualities of different airplanes.

Wood was the primordial material of airplane construction. Although Anthony Fokker—influenced by his chief designer, Reinhold Platz, who was a former welder—adopted welded steel tubing for his fuselages in 1916, by and large the airplanes of World War I were made of wood and fabric. Some were surprisingly sophisticated. The German firm Albatros, for instance, made beautifully streamlined, compound-curved fuselages of molded plywood in 1917. By 1918 Fokker had produced a wooden wing for the D.VIII fighter that would have looked perfectly in place a decade later on a Lockheed Vega. The preference for wood construction, particularly for wings, continued into the 1930s. Wood was a familiar material, inexpensive and easily repaired. Woodworkers were readily found or trained, and, as the importance of drag reduction came to be appreciated, the smooth, stiff surfaces of wooden wings were valued.

Wood and aluminum were, in some ways, interchangeable materials. The tensile strength of aircraft aluminum is 10 times that of Sitka spruce, but spruce has a tenth the weight of aluminum. (Sitka spruce, from the western forests of the U.S. and Canada, is the wood of choice for aircraft not because it is especially strong but because it is readily available in long, knot-free planks with straight grain.) But wood had some arguable advantages. Shaping and assembly of wood parts does not require exotic tools. Wood, unlike metal, does not fatigue. The great drawback of metal construction, before the advent of reliable adhesives, was its reliance on tens of thousands of rivets, which a pair of workers must install one at a time. Even apart from the labor saving, bonded joints had the advantage of avoiding the stress concentrations produced by rivets and the opportunities for hidden corrosion offered by overlapping metal joints.

There were metal-skinned airplanes in the 1920s, such as the Ford and Fokker Trimotors, but they were horrible, corrugated things. The Douglas DC-1—followed closely by the DC-2—with its smooth aluminum semi-monocoque construction and superb streamlining, was as stunning an innovation in 1933 as the SR-71 was in 1964. In the United States, Schatzberg argues, metal was perceived as synonymous with progress and modernity. Wood seemed to be a quaint material more appropriate to sailing ships. The hostility to wood, on grounds of supposedly poor durability, moisture absorption, and lack of uniformity, was sometimes quite palpable, but, Schatzberg suggests, was owing to an unconscious aversion to adjusting methods and expectations to the peculiarities of the material. When James “Dutch” Kindelberger, CEO of North American Aviation, complained to General K.B. Wolfe, head of the production division at Wright Field, the Army Air Corps’ testing center, about an Air Corps requirement for wooden fuselages for AT-6s, Wolfe did not hold back. “I would just like to just push a few of these [wooden] jobs out into the training crowd and let them see what they are up against,” he fumed. “We are just making a lot of trouble for ourselves on this wooden program.”

The British mindset was quite different. When the Air Ministry was considering de Havilland’s proposal of a fast, light bomber built of wood, the objections raised were to its lack of defensive armament, not to the material. De Havilland’s argument that the twin-engine Mosquito’s speed and range would protect it against German fighters eventually prevailed and proved to be correct.

- READ MORE: Technicalities: Piggybacks and Parasites

It may be that, apart from any cultural proclivity for wood as a raw material, the British acceptance of wooden construction had its roots in the remnants of an artisan culture that persisted in Europe well into the 20th century but was vanishing in the United States, thanks largely to Henry Ford. Wood construction, because of the dimensional instability of the material, often required some hand work preparatory to final assembly. The British willingness to employ files and sandpaper extended beyond woodwork. British Merlin engines were assembled with a similar acceptance of imprecision, and when the Packard company, contracted to produce Merlins in the U.S., received the British blueprints for the engine, it judged them unusable by American workers, who expected parts to be identical and fully interchangeable, and to fit perfectly on the first try.

It’s easy to grow sentimental over the special beauties of fine wood construction, be it in a desk, airplane, or old Chris-Craft boat. The most ambitious example to emerge during the war, however, aroused no such feeling and was also probably the most compelling proof that wood was a freak visitor from the past. It was Howard Hughes’ monster “Spruce Goose,” for a long time the world’s largest airplane. I climbed through it once, while it was still locked in a tin hangar at Long Beach, California. Its cavernous fuselage was built of molded panels of heat-cured, resin-bonded plywood, a process pioneered by American Virginius Clark in the 1930s. Standing at the base of its vertical fin, my eyes (but not my feet) following a ladder into its murky recesses, I thought of medieval bell towers and their twisting, claustrophobia-inducing stairs. Wherever I looked, however, I did not think about the future.

This column first appeared in the August 2023/Issue 940 print edition of FLYING.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox