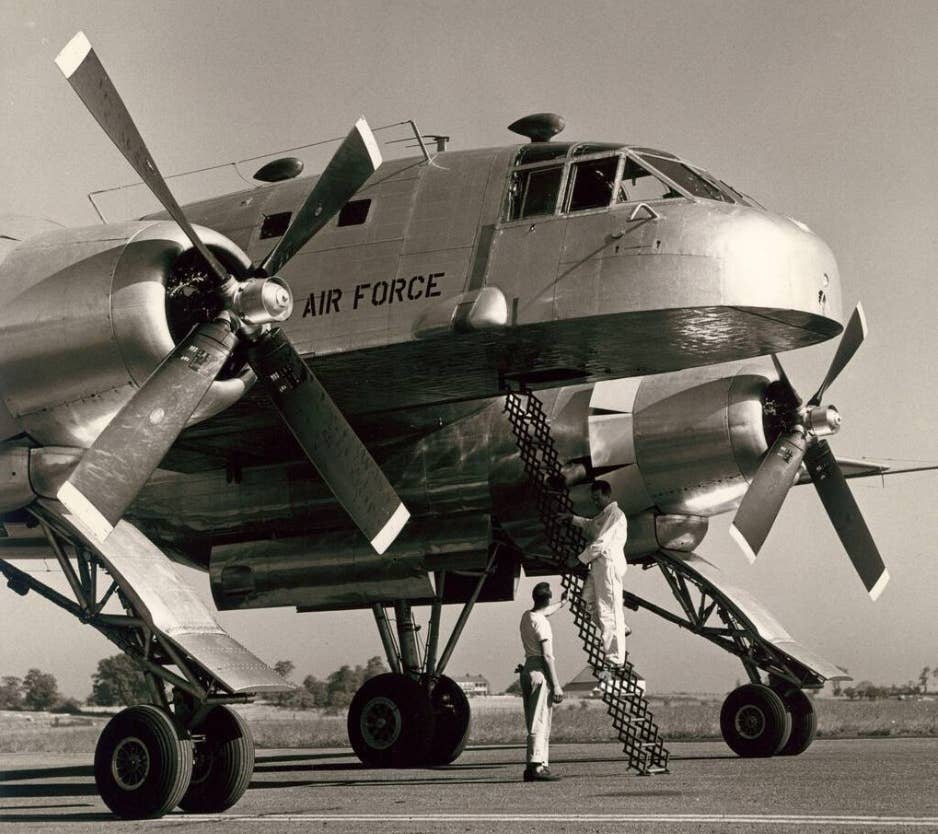

The Eagle DW-1 utilized high-aspect ratio wings to provide a more efficient and effective platform from which to spray crops. [Photo: Jason McDowell]

Every now and then you run across a dog that has completely mismatched body parts. A Doberman with tiny, stumpy legs, or a bulldog with floppy ears and a gangly build. Dogs that make you wonder how in the world their collection of genetic material ever made it through the final approval stage.

The Eagle Aircraft DW-1 is an agricultural airplane with a similarly bizarre set of characteristics. It was designed by a man named Dean Wilson, who also designed the Avid Flyer and the Global Explorer, a twin-engine amphibious aircraft optimized for the exploration of remote parts of the globe. In every case, Wilson prioritized function over form, and in every case, he delivered an aircraft that delivered on its technical promises.

“Do you know an aircraft that Jason should profile? E-mail us at editorial@flying.media”

For the DW-1, Wilson harnessed his experience with sailplanes and aerial application (crop dusting) to completely reimagine the agplane. An experienced sailplane instructor, he understood the benefits of a long wingspan with a correspondingly high aspect ratio. Such a configuration had the potential to reduce the wing loading and enable slower flight…both of which would allow an ag pilot to quicken their turns and spend more time actually spraying crops.

At the same time, a wing with a greater span would be inherently beneficial in that each pass would result in a wider swath of spray, reducing the number of passes required for each field. Wilson’s overall goal in designing the unique DW-1 was aimed at creating an agplane that was more efficient and thus more profitable than the competition.

The result was a biplane with seemingly mismatched components. Long, thin, sailplane-esque wings with a 15:1 aspect ratio were mounted to a fabric-covered steel tube fuselage. And while the prototype utilized a Jacobs radial engine, production aircraft would all be fitted with a sleekly cowled 300 horsepower Lycoming IO-540, an engine more commonly found on things like the Piper Navajo and Cessna 206.

The Eagle’s 55-foot wingspan dwarfed other similarly-powered agplanes such as the Piper Pawnee (36 feet), the Embraer Ipanema (38 feet), and the Cessna AgWagon (41 feet). At the same time, the Eagle’s 386 square foot wing area easily topped the others, which ranged from about 180 to 215 square feet. Clearly, Wilson wasn’t afraid to commit to his initial design concepts.

Wings of such length aren’t typically as maneuverable as shorter-span wings, however, particularly when filled with fuel and festooned with spray equipment. This presented a roadblock to Wilson’s goal of enabling the high roll rates necessary for quick 180-degree turns while spraying a field. The solution? Long, thin roll-control spoilers on each lower wing that worked in unison with the ailerons to deliver a quick, crisp roll rate.

When the Eagle entered production in the late 1970s, Wilson took advantage of a slowing economy by hiring a number of workers from the Bellanca aircraft company. He was able to use their significant experience in wooden aircraft structures and fabric covering to manufacture around 100 examples of the wooden-winged DW-1 and exported them as far as Australia and New Zealand. While the airplane was ultimately not profitable for the manufacturer, it performed its mission as designed and served its operators well for decades.

Today, 30 examples remain on the U.S. register. Largely hidden from public view by virtue of being based among remote, rural crops in the Midwest U.S., the Eagle is a unique blend of engineering that’s a particularly rare sight. But like a loyal mutt with a similarly mismatched set of parts, the end result is one that can be appreciated for its individuality.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox