Ultimate Issue: AOA Gets Revisited—Again

Designing an accurate angle-of-attack system represents only half the challenge.

There is also the problem, perhaps even more difficult than designing an angle-of-attack system, of how best to present the information to the pilot. [iStock]

For as long as I can remember—I started doing this in 1968—writers for FLYING and other aviation publications have been singing the praises of angle-of-attack (AOA) indicators.

They were rare in general aviation airplanes until 2014 when the FAA simplified the requirements for installing them. A proliferation of aftermarket AOA systems followed, ranging in price from around $300 to more than $3,000. I don’t know how widely these devices have been adopted, nor do I know whether any study has been made of their impact on the GA accident rate.

Despite its well-known shortcomings as a stall-warning device, the airspeed indicator remains the only AOA reference in most airplanes. It has the advantages of being a mechanically simple system, intuitive, and familiar. Speed is an everyday experience, while angle of attack, for most pilots, remains in the realm of the theoretical.

Theoretical or not, I think, to start with, that we could improve the terminology. “Angle of attack” is really a proxy for something else, namely “the amount of the maximum lift available that is currently in use.” So it would be more meaningful to speak of a “lift indicator,” “relative lift indicator,” or “lift fraction indicator.”

- READ MORE: The Craft of Providing Variety in Airplanes

One of the advantages of thinking in terms of lift fraction is that almost all of the important characteristic speeds of any airplane—the exceptions are the nonaerodynamic speeds, such as gear-and-flap-lowering speeds—fall close to the same fractions of lift regardless of airplane size, shape, or weight. Best L/D speed is at around 50 percent and 1.3 Vs at exactly 60 percent. Stall, obviously, is at 100 percent. A lift gauge is universal: It behaves, and can be used, in the same way in all airplanes.

A few years ago, in a column titled “A Modest Proposal,” I suggested demoting the hallowed airspeed indicator to a subsidiary role and replacing it with a large and conspicuous lift indicator. I borrowed the title from a 1729 essay by Jonathan Swift, the author of Gulliver’s Travels, in which he satirically proposed that poverty in Ireland might be relieved if the populace were to sell its manifestly too numerous babies to be eaten by the rich. My appropriation of Swift’s title was meant to suggest that I considered my proposal was about as likely to be adopted as his.

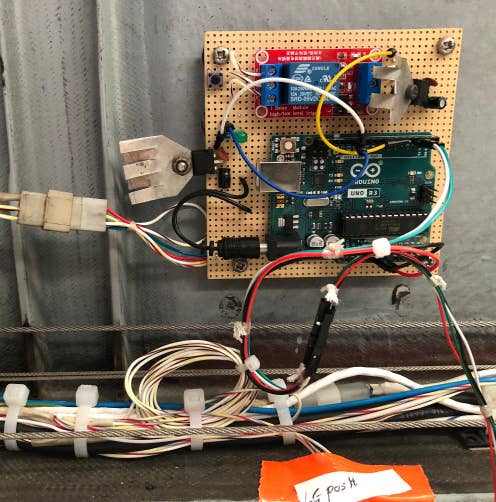

At the time I wrote my article, I was not yet aware of a 2018 paper by a team led by Dave Rogers, titled “Low Cost Accurate Angle of Attack System.” Using a simple underwing probe and electronic postprocessing, Rogers and his group achieved accuracy within a fraction of a degree of angle of attack with a system costing less than $100. That’s more accuracy than you really need, but better more than less.

- READ MORE: Looking at the Physics of STOL Drag

The low cost is made possible by the availability of inexpensive small computers— Rogers’ team used a $20 Arduino—that can be programmed to do the math needed to convert the pressure variations read by a simple probe into usable AOA data. Processing is necessary because the airplane itself distorts the flow field around it and makes it all but impossible to read AOA directly with a vane or pressure probe situated close to the surface of the aircraft. Besides, configuration changes, like lowering flaps, alter the lifting characteristics of the wing.

Designing an accurate system is only half the challenge, however. There is also the problem, perhaps even more difficult, of how best to present the information to the pilot. Little agreement exists among current vendors. Some presentations use round dials, some edgewise meters, some various arrangements of colored lights or patterns of illuminated V’s and chevrons resembling a master sergeant’s shoulder patch.

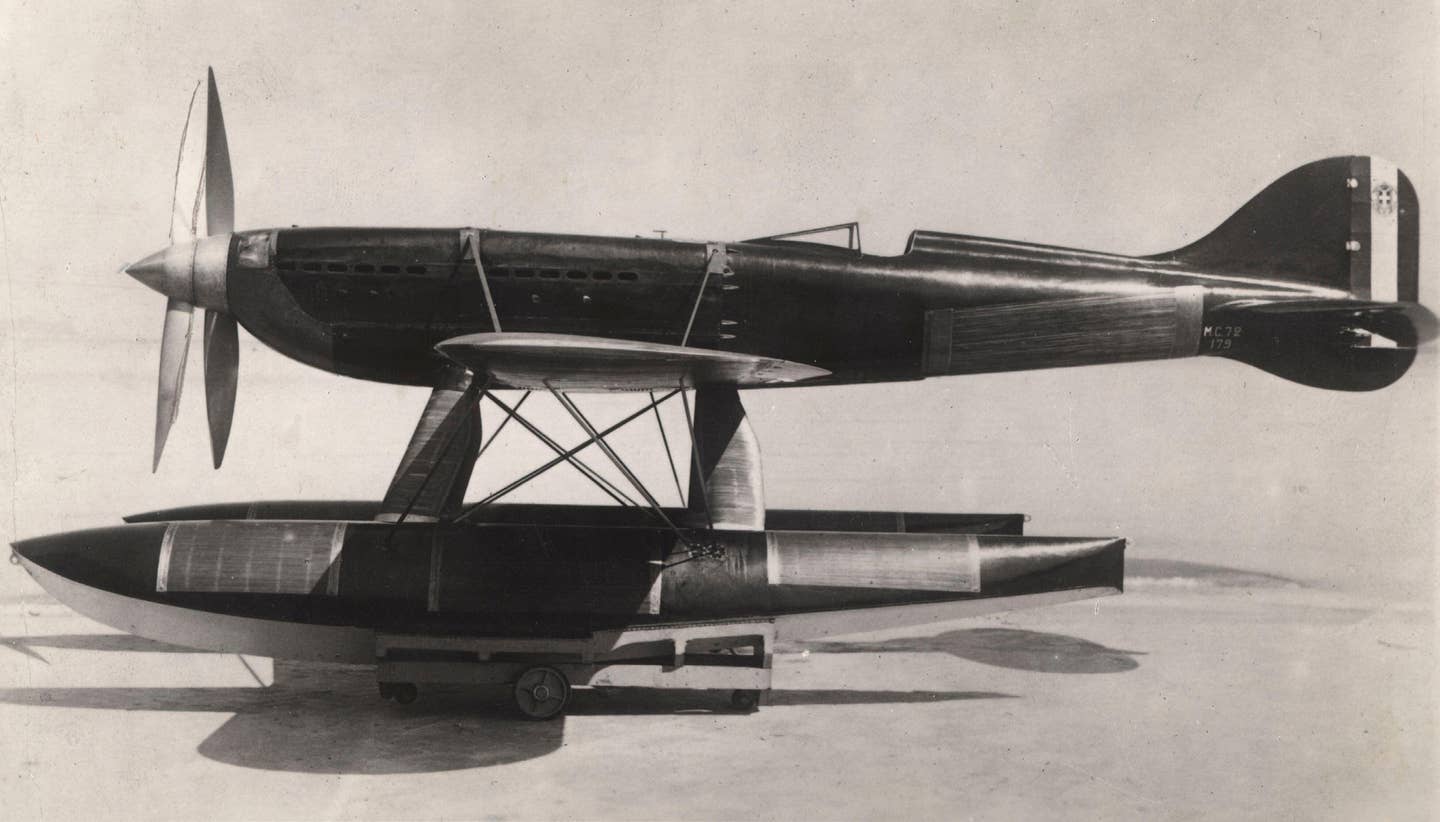

In 1973, the late Randy Greene of SafeFlight Corp. gave me one of his company’s SC-150 lift indicators for my then-just-completed homebuilt, Melmoth. The SC- 150 used a rectangular display with a moving needle. There was a central stripe for approach speed flanked by a couple of dots for climb and slow-approach speeds, and a red zone heralding the approach of the stall. The probe that sensed angle of attack was a spring-loaded, leading-edge tab, externally identical to the stall-warning tabs on many GA airplanes.

Apparently, some people mounted the SC-150’s display horizontally, but that made no sense to me at all. Given that I wanted it vertical, however, Greene and I did not see eye to eye about which end should be up. Greene was a jet pilot used to a lot of high-end equipment (SafeFlight made autothrottles, among other fancy stuff, for airliners). He understood the device as a flight director—as you slowed down, the needle should move downward, directing you to lower the nose.

I, who despite having acquired in my younger days a bunch of exotic ratings, am really just a single-piston-engine guy, saw it as analogous to an attitude indicator and thought that as the nose went up the needle ought to do the same. Greene saw the display as prescriptive; I saw it as descriptive.

Recently, Mike Vaccaro, a retired Air Force Fighter Weapons School instructor, test pilot, and owner of an RV-4, wrote to acquaint me with FlyONSPEED.org, an informal group of pilots and engineers working on (among other things) practical implementation of a lift-awareness system of the type described in Rogers’ paper. The group’s work, including computer codes, is publicly available. Its proposed instrument can be seen in action in Vaccaro’s RV-4 on YouTube.

The prototype indicator created by the FlyONSPEED group mixes descriptive and prescriptive cues. Two V’s point, one from above and one from below, at a green donut representing approach speed, 1.3 Vs, the “on speed” speed. The V’s are to be read as pointers meaning “raise the nose” and “lower the nose.” An additional mark indicates L/D speed. G loading, flap position, and slip/skid are also shown on the instrument, along with indicated airspeed.

Importantly, the visual presentation is accompanied by an aural one. As the airplane slows down, a contralto beeping becomes more and more rapid, blending into a continuous tone at the approach speed. If the airplane continues to decelerate, the beeping resumes, now in a soprano register, and becomes increasingly frenetic as the stall approaches. Ingeniously, stereo is used to provide an aural cue of slip or skid—step on the rudder pedal on the side the sound is coming from. The audio component is key: It supplies the important information continuously, without the pilot having to look at or interpret a display.

This system—it’s just a prototype, not a product—is pretty much what my “modest proposal” was hoping for, lacking only the 26 percent-of-lift mark that would indicate the maneuvering speed. Irish babies, beware.

Now I just have to figure out what we’ll do with all those discarded airspeed indicators.

This column first appeared in the Summer 2024 Ultimate Issue print edition.

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox